The ideal angle for e-skin energy storage

- Products researchers Sungwon Lee and also Koteeswara Reddy Nandanapalli at the Daegu Gyeongbuk Institute of Science and Technology (DGIST) developed the manufacture process with colleagues in Korea. A trick for success is splashing a specific quantity of graphene ink onto flexible substratums at a certain angle and temperature.

Lee claims "Demand for remote diagnosis and also wearable tools is quickly raising and hence, numerous researchers are concentrating their research study initiatives on developing various electronic skin tools, which needs exceptionally little and flexible power devices as a source of power."

When micro-supercapacitors are billed, positive and negative electric charges build up on their electrodes and also saved as power. These gadgets have brief charging and also releasing times compared to batteries, however they can't keep as much power.

Graphene is an encouraging product for boosting their energy storage space, as graphene electrodes are highly porous and so provide a bigger surface for the needed electrostatic reactions to happen.

Another means to improve micro-supercapacitor efficiency is by producing electrodes with interlocking teeth, like those of 2 combs, boosting the amount of power that can be saved. Yet this procedure is pricey and also does not service flexible, temperature-sensitive substratums.

The obvious remedy would certainly be to splashing of graphene onto a flexible substrate, however vertical splashing causes electrodes that aren't really porous and that have compact layers, providing poor efficiency.

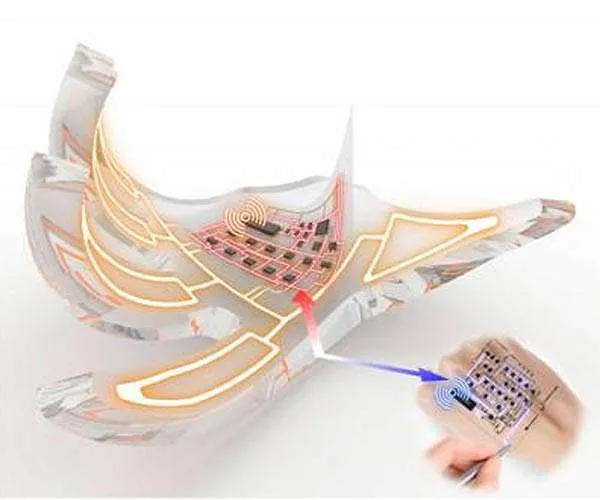

Lee, Nandanapalli, and their colleagues splashed graphene ink onto thin, flexible substrates, producing a paper-thin micro-supercapacitor with interlocking electrodes as well as exceptional efficiency.

The method, they checked out, was to spray 10 millilitres of graphene ink at a 45 degree angle and 80C temperature onto a flexible substrate. This caused the formation of porous, multi-layered electrodes. The team's micro-supercapacitor is 23 micrometres thin, ten times thinner than paper, and maintains its mechanical security after 10,000 bends.

It can save around 8.4 microfarads of fee per square centimeter (2 times more than that of the worth reported today) and has a power density of about 1.13 kilowatts per kilogram (4 times more than that of the Li-ion batteries). The group demonstrated it could be made use of in wearable devices that adhere to the skin.

"Our work reveals that it's possible to reduce the density of micro-supercapacitors for usage in flexible gadgets, without degrading their efficiency," states Lee. The group next aims to enhance the micro-supercapacitors' storage ability and power usage to make it practical for usage in real-world digital skin gadgets.

Also read