System can sanitize medical devices making use of solar warm

- Autoclaves, the tools used to sterilize clinical tools in medical facilities, facilities, and also doctors' and dentists' offices, require a consistent supply of pressurized heavy steam at a temperature of about 125 levels Celsius. This is normally provided by electrical or fuel-powered central heating boilers, yet in numerous backwoods, particularly in the creating world, power can be undependable or inaccessible, and fuel is costly.

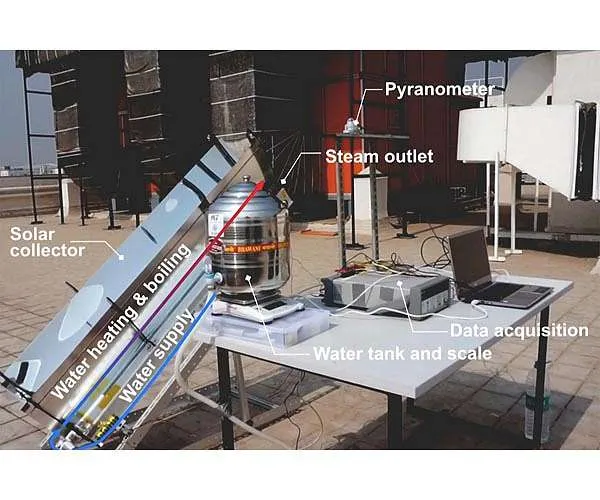

Now, a group of scientists at MIT as well as the Indian Institute of Technology has generated a method to create the needed heavy steam passively, making use of simply the power of sunlight, with no need for gas or electrical power. The tool, which would need a solar collector of about 2 square meters (or yards) to power a normal small-clinic autoclave, could maintain risk-free, clean and sterile equipment at low cost in remote places. A prototype was efficiently checked in Mumbai, India.

The system is defined in the journal Joule, in a paper by MIT college student Lin Zhao, MIT Professor Evelyn Wang, MIT Professor Gang Chen, and also 10 others at MIT and also IIT Bombay.

The trick to the new system is making use of optically clear aerogel, a product developed over the last few years by Wang and her collaborators. The product is essentially a lightweight foam made of silica, the material of beach sand, and is composed mostly of air. Light as it is, the product provides reliable thermal insulation, minimizing the rate of heat loss by tenfold.

This clear insulating material is bound onto the top of what is basically off-the-shelf equipment for generating solar hot water, which contains a copper plate with a heat-absorbing black finish, bound to a collection of pipelines on the underside. As the sunlight heats up home plate, water streaming via the pipelines beneath picks up that warmth.

But with the addition of the clear protecting layer ahead, plus refined aluminum mirrors on each side of the plate to direct added sunshine at home plate, the system can generate high-temperature heavy steam rather than just hot water.

The system makes use of gravity to feed water from a container into the plate; the vapor after that rises to the top of the room and also is fed out with another pipeline, which brings the pressurized steam to the autoclave. A stable supply of heavy steam need to be preserved for half an hour to accomplish appropriate sterilization.

Because much of the establishing globe encounters limited availability of reliable electrical power or affordable gas, "we saw this as a chance to consider how we can potentially develop a low-cost, passive, solar-driven system to produce vapor, at the conditions that are required for autoclaving or for clinical sanitation," discusses Wang, that is the Gail E. Kendall Professor of Mechanical Engineering as well as head of the mechanical engineering department.

Being able to test the system in Mumbai was a bonus, she says, because of the city's "relevance and importance" as the type of location that might benefit from such low-cost steam-generation equipment.

In the Mumbai tests, even though the sky was hazy and cloudy, providing only 70 percent insolation compared to a sunny day, the device succeeded in producing the saturated steam needed for sterilization for the required half hour period.

The test was carried out with a small-scale unit, only about a quarter of a square meter, about the size of a hand towel, but it showed that the steam production rate was sufficient that a similar unit of somewhere between 1 and 3 square meters would be sufficient to power a benchtop autoclave of the kind typically used in a doctor's office, Zhao says.

The main limiting factor for practical deployment of such devices is the availability of the aerogel material. One company, founded by Elise Strobach PhD '20, who is a co-author of this paper, is already attempting to scale up the production of transparent aerogel, for use in high thermal efficiency windows. But so far the material is only produced in small amounts using relatively expensive laboratory-grade supercritical drying equipment, so widespread adoption of such a sterilization system is likely still a few years off, the researchers say.

Since the other components, except for the aerogel itself, are already widely available at low cost throughout the developing world, fabrication and maintenance of such systems may ultimately be practical in the areas where they would be used. The parts needed for the quarter-square-meter prototype came to less than $40, Zhao says, so a system sufficient for a typical small autoclave would be likely to cost $160 or so, once the necessary aerogel material becomes commercialized.

" If we can get the supply of aerogel, the whole thing can be built locally, with local suppliers," he says.

The process could also be used for a variety of other purposes, the team says. For example, many food and beverage processing systems rely on high-temperature steam, which is typically provided by fossil-fuel powered boilers. Passive solar-powered systems to deliver that steam would eliminate the fuel costs, and so could be an attractive option in many industries, they say.

Ultimately, such systems should be much more cost-effective than systems that concentrate sunlight by tenfold or more to generate steam, because those require expensive mirrors and mountings, as opposed to the simplicity of this aerogel-based approach.

" This is a significant advance," says Ravi Prasher, a professor of mechanical engineering at the University of California at Berkeley and an associate director at Lawrence Berkeley National Laboratory, who was not involved in this work. "Generating high-temperature steam with high energy efficiency has been a challenge. Here the authors have achieved both."

" The quality of the research is very high," Prasher adds. "Access to passive sterilization techniques for low-income communities who do not have access to reliable electricity is a big deal. Therefore, the passive solar device developed by the MIT team is very significant in that regard."

Also read