SunDrive accomplishes 26.41% effectiveness with copper solar cell modern technology

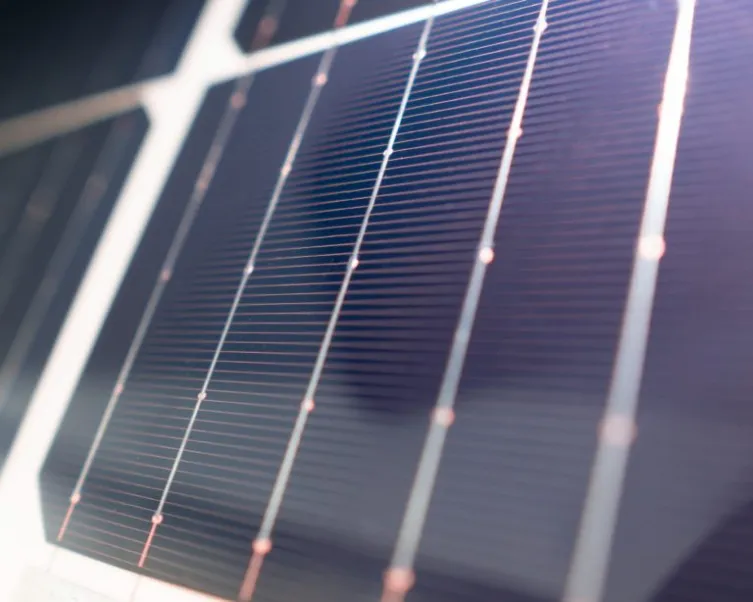

- Australian solar technology business SunDrive remains to excite with its copper-based solar cell modern technology, achieving 26.41% performance for a full-size silicon cell utilizing heterojunction modern technology compatible with automation

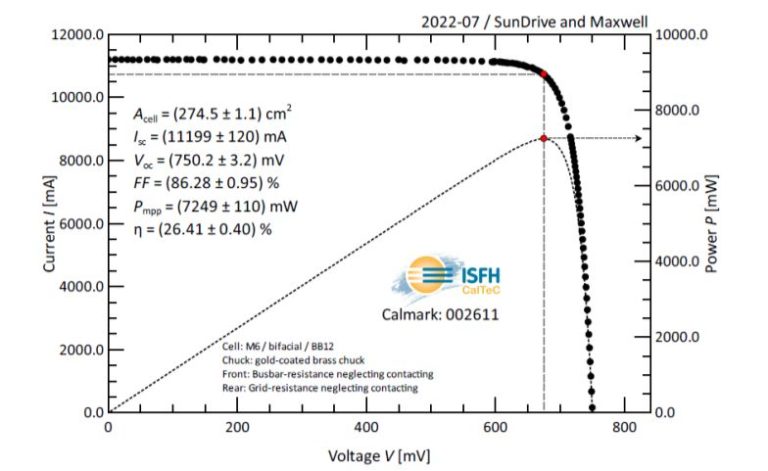

SunDrive has actually attained a 26.41% efficiency result on a full-size silicon heterojunction (HJT) solar cell including the company's copper-based technology making use of large-scale production refines supplied by the equipment manufacturer with China-based Maxwell Technologies.

Sydney-based SunDrive said the result, which improves the 26.07% efficiency mark the business introduced previously this year, has actually been formally validated by the Solar Energy Research Institute in Hamelin (ISFH). in Germany.

The business claimed that the HJT cell, with a complete location of 274.3 cm2 (M6 size), had actually been seen to enhance in all three key efficiency specifications, consisting of open-circuit voltage (Voc), short-circuit current (Isc) as well as the fill factor (FF). ), attributing the renovations to "several equipment as well as handling upgrades."

SunDrive claimed Maxwell's next-generation chemical vapor deposition (CVD) equipment incorporates the deposition of a bifacial microcrystalline silicon layer, further enhancing backside passivation as well as call resistance. Additionally, a lot more clear conductive oxide (TCO) layers were used making use of the most up to date physical vapor deposition (PVD) coating equipment from Maxwell.

SunDrive said making the solar cell electrodes utilizing the business's copper plating technology instead of conventional silver screen printing additionally played a key role in the efficiency renovations. SunDrive, which replaces the silver utilized in traditional solar cells with the more affordable and a lot more bountiful copper, stated it has actually improved its copper plating chemistry as well as handling sequence, achieving feature sizes of less than 10 µm at an aspect proportion. near to one

" What we have revealed is that copper can effectively replace silver in these next-generation solar cell frameworks, however much more significantly, effectiveness can be increased beyond degrees attainable with silver," the business said.

With solar PV readied to play a significant role in transitioning the world to a clean power future, SunDrive founder Vince Allen said copper is the key to opening the floodgates to extra efficient solar cell frameworks as well as Its use as opposed to silver could allow solar energy technology to reach its complete possibility.

" The solar cells that will certainly provide a lot of the world's future power requirements will be very different from the solar cells we have today," he claimed. "The efficiency, price and also scalability of products are vital to the continued development in fostering of solar energy.

" Copper has to do with 100 times cheaper per kilogram and about 1,000 times more plentiful than silver. And also in addition to the wealth and cost benefits of copper, we have actually located that we can improve efficiency beyond what can be accomplished with silver."

SunDrive will certainly now progress with plans to establish a pilot assembly line in mid-2023, with a scale to market entry later on in the year.

While an area for the organized production center has not been identified, Allen stated Australia has most of the ingredients needed to host a solar manufacturing market.

"We acknowledge that nations are progressively competing in this room, however, with the appropriate policy in position, Australia has the potential to be a global solar production powerhouse," he said.

Also read