Sticking

- A cell interconnection technique created by a Swedish firm assures lower-cost and also higher-throughput production of PERC and advanced silicon PV modules. The procedure is ready to move to pilot production, and its makers wish to play a role in the awaited European solar production renaissance.

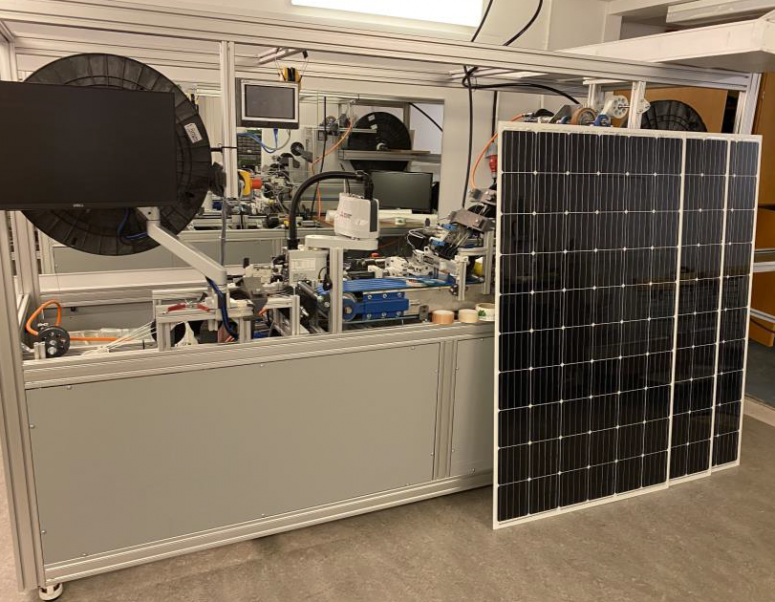

Swedish firm Sticky Solar Power states it is ready to move right into a brand-new stage of pilot manufacturing for its 'tape remedy' cell affiliation method. Sticky Solar stated the process has several advantages over present module manufacturing soldering techniques as well as should also contrast positively with Meyer Burger's SmartWire solution.

The heats associated with the soldering used in conventional module manufacturing indicate the method is unsuitable for high performance cell concepts such as heterojunction (HJT) products. With a shift toward roundwires and also multibusbar (MBB) modern technologies elevating more cell interconnection issues, producers, as ever, are waiting on an affordable procedure which can supply high throughput.

Sticky Solar's Tape Solution gets rid of soldering totally by instead placing a sticky tape around the interconnection bow which holds the cord in position via the taking place manufacturing stages. A firm link is then produced by the warmth as well as stress related to the module throughout lamination.

The highly transparent tape supposedly provides extremely solid ultraviolet (UV) resistance.

" Our process permits us to provide considerably lowered capex [capital expenditure] and regarded danger," said Sticky Solar joint president Beatriz Roza. "These are considerable advantages in the existing market."

The firm was not prepared to disclose throughput numbers however stated it could be substantially enhanced with the tape technique.

" We turn out the tape in a constant activity," stated fellow CEO Jonas Buddgård. "A robot positions the cells on the fly, there is no starting as well as quiting similar to soldering. The bottleneck in terms of cycle time is the robotic, and also we can enhance the number of robot arms."

By removing solder, the procedure can additionally reduce the amount of silver called for while dealing with the concern of exposure to high temperatures in HJT and other high-efficiency-cell manufacturing. The procedure has actually only been tested with a flat ribbon so far however there are plans to test with round wire and having it held in area by tape could provide a solution to keeping such products lined up.

Pilot

Sticky Solar stated it has had strong rate of interest from suppliers and prepares to relocate into pilot manufacturing. The firm stated it wants to work closely with consumers to settle issues which may not have been evident at the R&D phase. Sticky Solar has actually obtained EU financing for the pilot manufacturing phase and also intends to start looking for manufacturers to join its task this year.

" The next two or three years will be very intriguing in terms of the establishment of production in Europe, the home window is certainly there for novel procedure improvements," said Buddgård. "We want to join the various solar production efforts, not the very least due to the fact that this may open some early contacts with these manufacturing projects."