Steel yourselves, Swinburne researcher uses solar to decarbonise steel

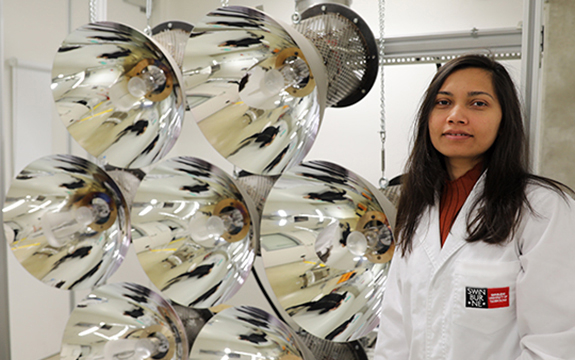

- Swinburne PhD candidate Suneeti Purohit's remarkable double innovation utilises solar power to decarbonise the steel industry and save iron ore miners cash.

Swinburne University of Technology (Swinburne) PhD candidate Suneeti Purohit has been known for her outstanding research incursions to revolutionising the steel sector with solar energy. Purohit inventions have won the 2019 AMP Amplify Ignite contest.

Recent investigation by Wood Mackenzie projects the Asia Pacific's Decarbonisation bill could reach US$3.5 trillion by 2040. US$3.5 trillion is enough to buy everybody in Sydney a home at Sydney's inflated home prices, or rather, it is enough to buy everybody one avocado toast in a stylish cafe.

Luckily, Swinburne PhD candidate Suneeti Purohit is looking out for her fellow avocado smash loving Australians. Purohit is trying to use solar power to convert iron ore into molten iron.

Like Dale from the Australian cult classic movie The Castle, Australians like to dig holes, and there's nothing Australians like to dig more than iron ore. Australia is the world's biggest manufacturer and exporter of iron ore, the important component of steel. Alas, the method is a significant carbon emitter. According to Swinburne, in 2017-2018 international steel production was approximately 1800 million tonnes, roughly 30 percent of total industrial carbon dioxide emissions.

The very first of the innovative approaches sees concentrated solar heat utilized as a replacement of almost 50 percent of fossil fuels used in iron making.

The second strategy involves the controlling of iron carbon emissions through the development of an alternate agglomeration path of magnetite ore. The present processing of magnetite ore necessitates the inclusion of oxygen to oxidise the magnetite and help it become reducible. However, this procedure subsequently requires the elimination of the oxygen by burning extra carbon, roughly 150 kg additional carbon emission for each tonne of iron manufacturing, notes Purohit.

Also read

- Revolutionizing Solar Energy: Key to Efficient Organic Cells

- Revolutionary Solar Cells Power Drone with Unprecedented Efficiency

- Unlocking Perovskite Secrets: Next-Gen Solar Cell Breakthrough

- Ultra-lightweight Perovskite Solar Cells Power Energy-Autonomous Drones

- Revolutionary CFS Technique for Rapid Perovskite Solar Cells