Solar modules made from perovskite product get a boost of stability as well as performance to change the sector

- Researchers from the Okinawa Institute of Science and also Technology Graduate University (OIST) have developed next-generation solar modules with high efficiency and great security. Made using a type of material called perovskites, these solar modules can keep a high performance for over 2000 hours. Their searchings for, reported 20th July 2020 in leading journal, Nature Energy, have lightened up prospects of commercialization.

Perovskites have the potential to change the solar innovation market. Adaptable and also light-weight, they promise a lot more versatility than the heavy as well as inflexible silicon-based cells currently controling the market. Yet scientists must get over some significant difficulties prior to perovskites can be marketed.

" There are three conditions that perovskites have to meet: they should be cheap to generate, highly efficient and have a lengthy lifespan," stated Professor Yabing Qi, head of the OIST Energy Materials as well as Surface Sciences Unit, that led this research study.

The price of making perovskite solar cells is low, as the inexpensive resources require little power to procedure. And in just over a years, scientists have made big strides in boosting exactly how effectively perovskite solar cells convert sunshine to electricity, with performance levels currently similar to those of silicon-based cells.

Nonetheless, when scaled up from small solar cells to bigger solar modules, the performance levels of perovskites drop. This is troublesome as industrial solar technology needs to remain reliable at the size of photovoltaic panels, a number of feet in size.

" Scaling-up is extremely requiring; any problems in the product become more pronounced so you need high-quality products and also much better fabrication strategies," discussed Dr. Luis Ono, a co-author of this research study.

The instability of perovskites is one more vital issue under intense examination. Industrial solar cells need to be able to stand up to years of operation however presently perovskite solar cells degrade quickly.

Building up the layers

Teacher Qi's team, supported by the OIST Technology Development and also Innovation Center's Proof-of-Concept Program, resolved these security and also performance problems utilizing a new strategy. Perovskite solar tools are comprised of multiple layers-- each with a certain feature. Instead of concentrating on just one layer, they looked at the total efficiency of the tool as well as how the layers interact with one another.

The active perovskite layer, which absorbs sunlight, hinges on the center of the tool, sandwiched between the other layers. When photons of light strike the perovskite layer, negatively-charged electrons harness this energy as well as "jump" to a greater power degree, leaving behind positively-charged "holes" where the electrons made use of to be. These charges are then diverted in opposite directions right into electron as well as hole transport layers above as well as below the energetic layer. This develops a circulation of charge-- or power-- that can leave the solar gadget via electrodes. The gadget is additionally enveloped by a safety layer that reduces deterioration as well as stops toxic chemicals from dripping into the setting.

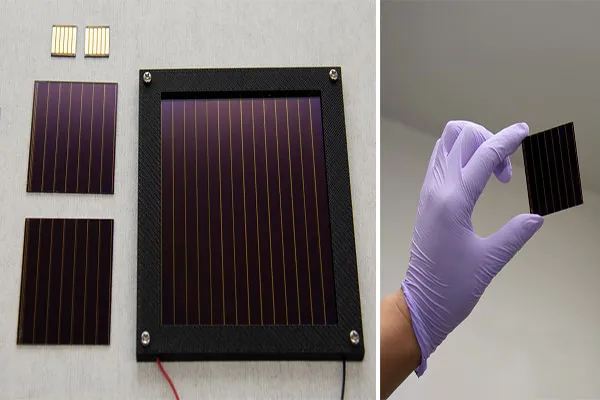

In the study, the scientists dealt with solar modules that were 22.4 cm2.

The researchers first boosted the user interface in between the perovskite energetic layer as well as the electron transport layer, by including a chemical called EDTAK in between the two layers. They found that EDTAK protected against the tin oxide electron transport layer from reacting with the perovskite active layer, increasing the security of the solar module.

The EDTAK additionally improved the effectiveness of the perovskite solar module in 2 different methods. To start with, potassium in the EDTAK moved right into the energetic perovskite layer and "recovered" tiny issues on the perovskite surface area. This avoided these problems from trapping the moving electrons and holes, allowing more electrical energy to be created. The EDTAK likewise boosted efficiency by boosting the conductive residential or commercial properties of the tin oxide electron transport layer, making it less complicated to collect electrons from the perovskite layer.

The scientists made comparable enhancements to the interface in between the perovskite active layer and also the hole transportation layer. This time, they added a kind of perovskite called EAMA in between the layers, which boosted the ability for the hole transportation layer to get holes.

The EAMA-treated device also showed far better stability under humidity and temperature level examinations. This resulted from just how the EAMA communicated with the surface area of the perovskite active layer, which is a mosaic of crystal grains. In solar gadgets without EAMA, the researchers saw that splits based on the surface of the active layer, which stemmed from the limits between these grains. When the researchers included EAMA, they observed that the extra perovskite material loaded the grain borders and also quit wetness from going into, preventing these fractures from forming.

The group also customized the hole transportation layer itself, by mixing in a percentage of polymer called PH3T. This polymer improved dampness resistance by offering the layer with water-repellant properties.

The polymer additionally fixed a significant issue that has actually previously hindered renovations to lasting stability. The electrode on top of the perovskite solar module is developed from thin strips of gold. But over time, small gold particles migrate from the electrode, via the hole transport layer as well as into the energetic perovskite layer. This irreversibly impairs efficiency of the gadget.

When the researchers incorporated PH3T, they located that the gold bits moved into the gadget more slowly which dramatically enhanced the module's life-span.

For their final improvement, the scientists included a slim layer of the polymer, parylene, in addition to glass, to give a protective covering to the solar module. With this added security, the solar modules preserved about 86% of their preliminary efficiency, also after 2000 hrs of constant illumination.

In cooperation with Dr. Said Kazaoui at National Institute of Advanced Industrial Science as well as Technology (AIST), the OIST group tested the boosted solar modules and also got an efficiency of 16.6%-- an extremely high effectiveness for a solar module of that dimension. The scientists now aim to accomplish these alterations on bigger solar modules, blazing a trail towards the advancement of massive, industrial solar innovation in the future.

Also read