Solar hydrogen: Photoanodes promise high efficiencies

- Photoanodes constructed from steel oxides are thought about to be a viable solution for the production of hydrogen with sunlight. α-SnWO4 has optimum digital properties for photoelectrochemical water splitting with sunshine, but rusts conveniently.

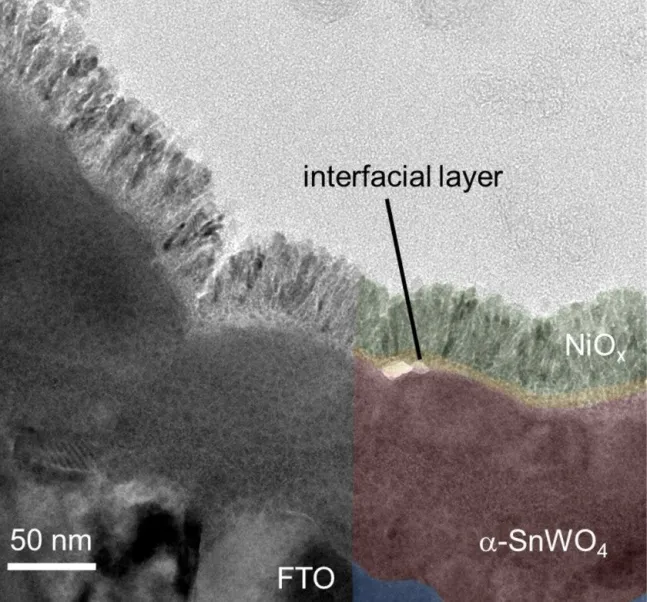

Safety layers of nickel oxide prevent corrosion, however reduce the photovoltage as well as restrict the effectiveness. Currently a team at HZB has actually checked out at BESSY II what occurs at the user interface in between the photoanode and the safety layer. Combined with academic methods, the dimension information disclose the presence of an oxide layer that impairs the effectiveness of the photoanode.

Hydrogen is a crucial consider a sustainable energy system. The gas stores energy in chemical kind as well as can be made use of in several means: as a fuel, a feedstock for various other gas as well as chemicals or perhaps to produce electricity in gas cells. One solution to produce hydrogen in a climate-neutral way is the electrochemical splitting of water with the help of sunlight. This needs photoelectrodes that provide a photovoltage as well as photocurrent when exposed to light and at the same time do not rust in water. Metal oxide compounds have encouraging requirements for this. As an example, solar water splitting devices using bismuth vanadate (BiVO4) photoelectrodes achieve already today ~ 8% solar-to-hydrogen efficiency, which is close to the material's theoretical maximum of 9%.

Academic limit is 20% in α-SnWO4

To achieve effectiveness past 9%, new materials with a smaller band void are required. The metal oxide α-SnWO4 has a band gap of 1.9 eV, which is flawlessly suited for photoelectrochemical water splitting. In theory, a photoanode constructed from this product might transform ~ 20% of the irradiated sunlight right into chemical energy (kept in the form of hydrogen). Unfortunately, the substance weakens extremely swiftly in an aqueous setting.

Protection versus deterioration includes a cost

Thin layers of nickel oxide (NiOx) can protect the α-SnWO4 photoanode from corrosion, yet were discovered to also substantially minimize the photovoltage. To recognize why this holds true, a team led by Dr. Fatwa Abdi at the HZB Institute for Solar Fuels has actually examined the α-SnWO4/ NiOx interface in detail at BESSY II

User interface checked out at BESSY II.

" We studied samples with various densities of NiOx with tough X-ray photoelectron spectroscopy (HAXPES) at BESSY II as well as interpreted the measured information with results from estimations and also simulations," says Patrick Schnell, the very first author of the research study and a Ph.D. student in the HI-SCORE International Research School at HZB. "These outcomes show that a thin oxide layer kinds at the interface, which decreases the photovoltage," explains Abdi.

Outlook: Better protection layers

On the whole, the research study provides brand-new, basic understandings into the complex nature of user interfaces in steel oxide-based photoelectrodes. "These understandings are extremely practical for the development of low-cost, scalable steel oxide photoelectrodes," says Abdi. α-SnWO4 is particularly appealing in this regard. "We are presently dealing with an alternate deposition process for NiOx on α-SnWO4 that does not bring about the formation of an interfacial oxide layer, which is likely to be SnO2. If this achieves success, we anticipate that the photoelectrochemical performance of α-SnWO4 will enhance substantially."

Also read