Scientists take on a brand-new possibility to create high-energy batteries

- In the last few years, lithium-ion batteries have actually progressed at providing power to Soldiers in the field, yet the present generation of batteries never ever reaches its greatest power possibility. Military scientists are exceptionally concentrated on fixing this obstacle as well as supplying the power Soldiers need.

At the U.S. Army Combat Capabilities Development Command's Army Research Laboratory, in partnership with the University of Maryland, researchers might have discovered a remedy.

" We are really thrilled to show a brand-new electrolyte style for lithium ion batteries that boosts anode capability by greater than 5 times contrasted to standard techniques," stated Army researcher Dr. Oleg Borodin. "This is the following action required to relocate this innovation more detailed to commercialization."

The group made a self-healing, safety layer in the battery that substantially reduces the electrolyte as well as silicon anode destruction procedure, which can expand the life expectancy of future generation lithium-ion batteries.

Their most recent battery layout enhanced the variety of feasible cycles from 10s to over a hundred with little destruction. The journal Nature Energy released their searchings for.

Below's just how a battery functions. A battery shops chemical power and also transforms it right into electric power. Batteries have 3 components, an anode (-), a cathode (+), and also the electrolyte. An anode is an electrode where the standard existing becomes part of a polarized electric gadget. This contrasts with a cathode, whereby present leaves an electric gadget.

The electrolyte maintains the electrons from going straight from the anode to the cathode within the battery. In order to produce much better batteries, Borodin claimed, you can raise the ability of the cathode as well as the anode, yet the electrolyte needs to work in between them.

Lithium-ion batteries usually utilize graphite anodes, which have an ability of concerning 370 milliamp hrs (mAh) per gram. However anodes constructed of silicon can supply regarding 1,500 to 2,800 mAh per gram, or a minimum of 4 times as much capability.

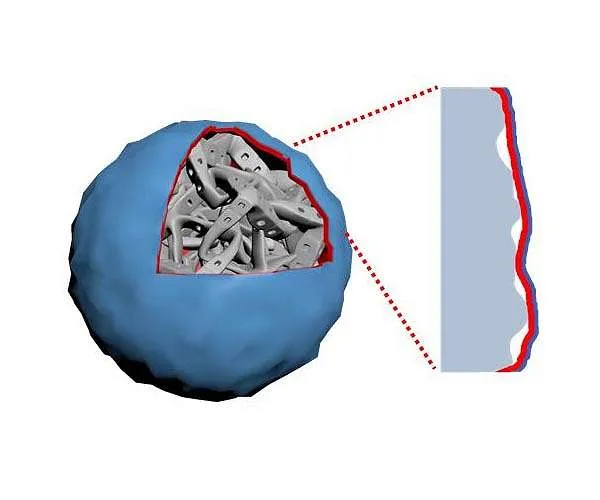

The scientists claimed silicon bit anodes, in contrast to conventional graphite anodes, offer exceptional options, yet they additionally deteriorate much quicker. Unlike graphite, silicon expands as well as agreements throughout a battery's procedure. As the silicon nanoparticles within the anode obtain bigger, they typically split the safety layer - called the strong electrolyte interphase - that borders the anode.

When anode bits make straight call with the electrolyte, the strong electrolyte interphase kinds normally. The resulting obstacle stops more responses from taking place and also divides the anode from the electrolyte. However when this safety layer ends up being broken, the freshly revealed anode bits will certainly respond constantly with electrolyte up until it goes out.

" Others have actually attempted to tackle this issue deliberately a safety layer that broadens when the silicon anode does," Borodin claimed. "However, these approaches still trigger some electrolyte destruction, which dramatically reduces the life time of the battery as well as the anode."

The joint group at the University of Maryland and also the Army Research Laboratory chose to attempt a brand-new method. Rather than a flexible obstacle, the scientists developed an inflexible obstacle that does not disintegrate - also when the silicon nanoparticles broaden. They established a lithium-ion battery with an electrolyte that developed a stiff Lithium Fluoride strong electrolyte interphase, or SEI, when electrolyte communicates with the silicon anode bits and also considerably lowered electrolyte destruction.

" We effectively prevented the SEI damages by developing a ceramic SEI that has a reduced fondness to the lithiated silicon fragments, to ensure that the lithiated silicon can move at the user interface throughout quantity modification without harming the SEI," claimed Prof. Chunsheng Wang, a teacher of Chemical as well as Biomolecular Engineering at the University of Maryland. "The electrolyte layout concept is global for all alloy anodes and also opens up a brand-new possibility to establish high-energy batteries."

The battery layout that Borodin and also Wang's team developed showed a coulombic [the fundamental device of electrical cost] performance of 99.9 percent, which implied that just 0.1 percent of the power was shed to electrolyte destruction each cycle.

This is a substantial enhancement over traditional layouts for lithium-ion batteries with silicon anodes, which have a 99.5-percent performance. While apparently tiny, Borodin claimed this distinction converts to a cycle life greater than 5 times much longer.

" Experiments carried out by Dr. Chunsheng Wang's team at the University of Maryland revealed that this brand-new technique achieved success," Borodin claimed. "However, it succeeded not just for silicon however additionally for light weight aluminum as well as bismuth anodes, which reveals the universality of the concept."

The brand-new style additionally included a number of various other advantages. The battery's greater ability enabled the electrode to be significantly thinner, that made the billing time much faster as well as battery itself a lot lighter. Additionally, the scientists located that the battery can deal with cooler temperature levels far better than regular batteries.

" For routine batteries, chillier temperature levels slow-moving diffusion and also might also ice up the fluids inside the batteries," Borodin claimed. "But since our layout has a much greater capability, hence ions need to diffuse much shorter ranges, causing a considerably enhanced reduced temperature level procedure, which is essential for warfighters running in cool environments."

The group gave thanks to the ARL Enterprise for Multiscale Modeling of Materials program for its assistance throughout the study initiative until now.

According to Borodin, the following action in the study is to create a bigger cell with a greater voltage utilizing this layout. Taking into account this objective, the group is presently exploring innovations right into the cathode side of the lithium-ion battery.

Also read