Scientists make next-generation, high-toughness battery component

- A team of Brown University researchers has actually discovered a method to double the durability of a ceramic product used to make solid-state lithium ion batteries. The approach, explained in the journal Matter, could be beneficial in bringing solid-state batteries to the mass market.

" There's big interest in changing the liquid electrolytes in current batteries with ceramic materials due to the fact that they're safer as well as can give higher power thickness," claimed Christos Athanasiou, a postdoctoral scientist in Brown's School of Engineering and lead writer of the research study. "So much, study on solid electrolytes has concentrated on maximizing their chemical buildings. With this job, we're focusing on the mechanical homes, in the hope of making them much safer as well as extra practical for extensive use."

The electrolyte is the obstacle in between a battery's cathode as well as anode where lithium ions flow throughout billing or discharging. Liquid electrolytes function pretty well - they're found in a lot of batteries being used today - however they have some troubles. At high currents, little filaments of lithium steel can form inside the electrolytes, which create batteries to short circuit. And also since fluid electrolytes are also extremely combustible, those shorts can result in fires.

Strong ceramic electrolytes aren't flammable, and there's proof that they can protect against the formation of lithium filaments, which could make it possible for batteries to operate at greater currents. Nonetheless, ceramics are extremely fragile products that can fracture during the manufacturing procedure and throughout usage.

For this new research study, the researchers intended to see if instilling a ceramic with graphene - a super-strong carbon-based nanomaterial - might raise the product's crack strength (a material's capacity to withstand cracking without falling apart) while maintaining the electronic homes needed for electrolyte function.

Athanasiou collaborated with Brown engineering teachers Brian Sheldon as well as Nitin Padture, that for several years have utilized nanomaterials to strengthen ceramics for use in the aerospace market. For this work, the scientists made tiny platelets of graphene oxide, mixed them with powder of a ceramic called LATP, and then warmed the mixture to form a ceramic-graphene composite.

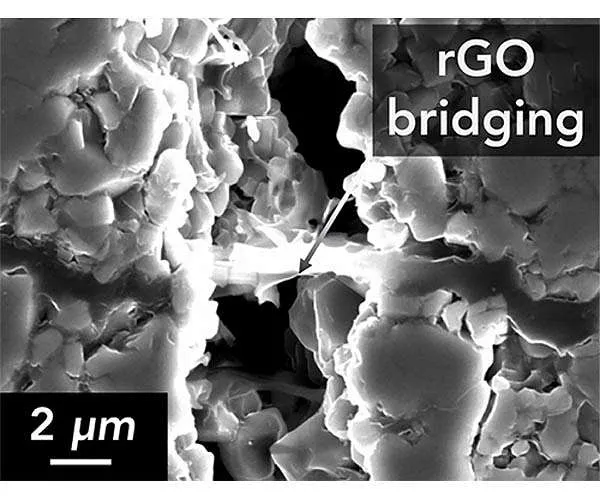

Mechanical testing of the composite revealed a greater than two-fold rise in strength contrasted to the ceramic alone. "What's taking place is that when split starts in a product, the graphene platelets basically hold the broken surfaces together to ensure that even more energy is needed for the crack to run," Athanasiou claimed.

Experiments also revealed that the graphene really did not interfere with the electrical properties of the material. The trick was making certain the correct amount of graphene was contributed to the ceramic. Insufficient graphene wouldn't achieve the toughening effect. Too much would certainly trigger the product to become electrically conductive, which is not desired in an electrolyte.

" You desire the electrolyte to conduct ions, not power," Padture said. "Graphene is a great electric conductor, so people might think we're shooting ourselves in the foot by placing a conductor in our electrolyte. However if we maintain the focus low sufficient, we can maintain the graphene from carrying out, and also we still get the structural benefit."

Taken together, the outcomes suggest that nanocomposites can provide a path ahead to making much safer strong electrolytes with mechanical properties to be made use of in day-to-day applications. The group intends to proceed working to boost the product, trying nanomaterials aside from graphene as well as different types of ceramic electrolyte.

" To our expertise, this is the toughest strong electrolyte that any person has actually made to date," Sheldon claimed. "I think what we've revealed is that there's a great deal of assurance being used these composites in battery applications."

Also read

- Pace Digitek switches on 2.5-GWh battery-storage plant in Karnataka

- CATL-led Indonesia Battery Integration Project breaks ground—US $6 billion for a full value-chain hub

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record

- EDF Acquires 500-MW Gate Burton Solar Project from Low Carbon