Scientists fabricate flexible perovskite solar cells by means of blade coating in ambient problems without making use of toxic solvents

- Researchers at University of Rome "Tor Vergata"'s CHOSE (Centre for Hybrid and also Organic Solar Energy) as well as CNR-ISM Institute of Structure of Matter have deposited flexible perovskite solar modules without making use of toxic solvents, by means of blade coating in ambient air. 14% PCE was reportedly acquired with the optimization of coating parameters and also using additives.

The scalable ambient air deposition of perovskite solar gadgets stays a major difficulty of this modern technology. In addition, toxic solvents are routinely made use of in perovskite layer deposition, which can harm the atmosphere and also threaten the security of possible production lines. In this current work, the group took care of to attend to these issues as well as fabricate lasting flexible perovskite solar modules (flex-PSMs), in which all layers were transferred using a blade coating in ambient air without the usage of toxic solvents.

Double-cation Cs0.15FA0.85PbI3-xBrx-based perovskite was blade covered in two actions as the absorber and also the coating specifications were optimized. The team found that proper drying out of the primary step is essential to acquire top notch perovskite films with the ideal phase of the perovskite. The researchers improved the morphology as well as restricted deep spaces in the perovskite layer by additive engineering as well as gotten 14% effectiveness.

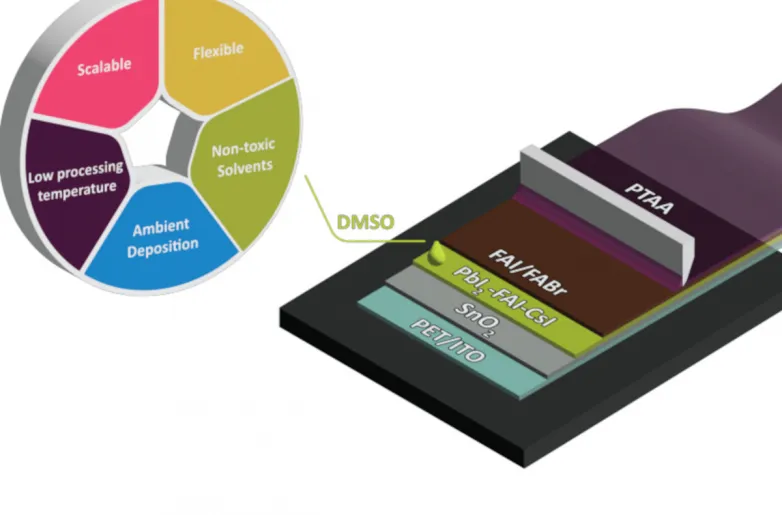

The team utilized the two-step blade coating technique to deposit a perovskite layer at low temperature level in ambient air utilizing DMSO just as the solvent for the first step and isopropyl alcohol (IPA) for the second step.

Low-temperature deposition of DMSO-based ink was presented to use on flexible substratums. Previous works on single-step deposition of DMSO-based perovskite service, utilizing the blade coating strategy needed high substrate temperature level (150 ° C) or high annealing temperature (170 ° C). On top of that, the previously reported gadgets were fabricated under a nitrogen environment.

The scientists fabricated flexible perovskite solar cells with a planar N-I-P device architecture of PET/ ITO/ SnO2/ Cs0.15FA0.85PbI3-xBrx/ PTAA/ Au in ambient air with a relative moisture of 30-35%. Solar cells were blade coated on large substrates (5 × 7 cm2) however determined on tiny scale with 0.09 cm2 energetic location, as well as the champion tool achieved 14.08% PCE.

The team provided in this current work a fully-blade coated as well as flex-PSM with a 9.7 × 9.7 cm2 (94 cm2) aperture location. They stated that the process was shown to be transferable to bigger substratums up to 13 × 13 cm2, and also thatfurther efforts need to be concentrated on enhancing the efficiency of these ambient-air fabricated modules.

Also read