Scientists establish method for boosting the capacity of next-generation metal-ion battery cathode materials

- Researchers at Skoltech Center for Energy Science and Technology have established an enriched and scalable strategy for boosting the capacity of a broad series of metal-ion battery cathode materials. These searchings for, published in Journal of Products Chemistry A, can be beneficial for creating a new generation of sophisticated rechargeable energy storage devices.

Development of modern-day lithium-ion batteries ended up being possible because of a number of scientific breakthroughs. Among them, made by a Nobel laureate John B. Goodenough, was the growth of cathode materials which contain reversibly extractable lithium ions. Execution of these products assisted to prevent hazardous anodes, such as lithium steel. However, troubles including limited capability, modest cycling security, low charge-discharge rate, issues with environmental kindness, etc, still had to be addressed.

Over the years, scientists have actually been putting tremendous initiative into creating far better battery materials. Because of this, various cathode products with eye-catching properties have actually been proposed. Nevertheless, the batteries that rely upon these materials can often reach their complete energy thickness only when they contain risky, highly reactive anodes with extractable cations. It is brought on by the absence of mobile metal ions in the cathodes. This issue brings about the limited ability and, in many cases, makes complex sensible application of otherwise appealing products.

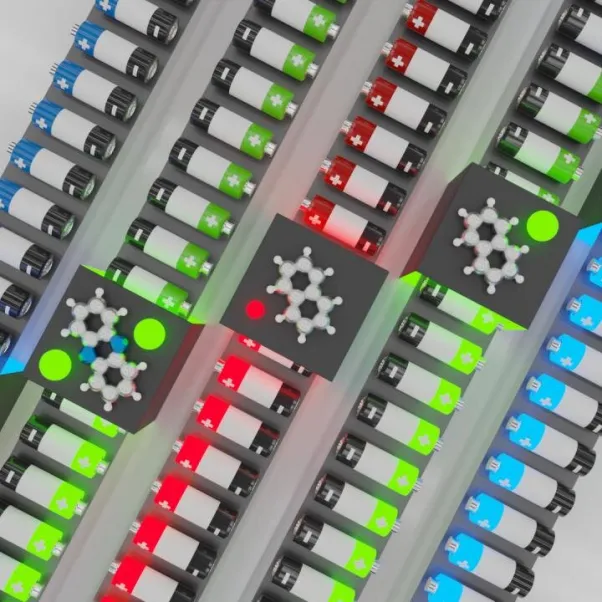

Skoltech Ph.D. trainee Roman Kapaev under guidance of Prof. Keith Stevenson demonstrated how this trouble can be resolved for a broad series of materials. It was suggested to treat the cathodes with options of decreasing agents, which are alkali steel salts stemmed from fragrant substances, as an example, naphthalene or phenazine.

An essential benefit of the approach is its scalability. The procedure calls for no sophisticated problems and is relatively safe. In addition, the lowering agents can be reused after they respond with the cathodes since their redox chemistry is reversible. These functions make the method guaranteeing for large-scale applications.

This technique is suitable for a wide range of natural and not natural battery materials. Additionally, it ended up being suitable not just for lithium-ion batteries, however also for salt- and potassium-ion batteries, which are possibly much more lasting and lower-cost energy storage devices. It was possible to control the content of steel ions in the cathodes by changing the amount of the minimizing representatives or their oxidation capacities.

" The method can function as an effective toolkit, which might be made use of to enhance the performance of numerous battery products," states Roman Kapaev. "It is likewise a straightforward as well as low-cost approach with recyclable reagents, so we believe that it appropriates for big scale useful applications."

Also read