Researchers publish perspective on silicon-based microparticle anodes for lithium-ion batteries

- Silicon is one of one of the most appealing anode products for high-energy lithium-ion batteries. Nonetheless, silicon-based anodes are not being extensively utilized yet as a result of a series of challenges that should be resolved before silicon can be commercially applied in lithium-ion batteries.

A research team from Huazhong University of Science and Technology has published a review perspective paper summarizing the obstacles, laying out the current approaches for engineering silicon-based anodes, and looking to the future leads for this encouraging anode product.

Their review perspective is released in the journal Nano Research Energy.

"In this review, we aim to provide some useful guidelines for the practical application of microscale silicon-based anodes by summarizing the advancement of silicon-based electrodes made by commercial silicon microparticles from the perspective of automation, such as basic materials, preparation process, yield, and ecological friendliness," said Xianluo Hu, a professor in the School of Materials Science and Engineering at Huazhong University of Science and Technology.

While silicon holds strong possibility as an anode prospect for next-generation lithium-ion batteries, there are several difficulties to be conquered. First, the group notes that nanotechnology, which makes it possible for electrode structural stability and long-term cycling, fails to meet the needs of industrial applications. This is because of its reduced tap density, considerable side reaction, reduced volumetric capacity, and complicated manufacturing process with reduced returns.

Second, the group notes that despite the fact that the design of microscale silicon-based anodes has remarkably boosted the overall efficiency of the electrode, the production procedures still include elaborate manufacture steps. These intricate steps lead to higher energy consumption, environmental pollution, and low yields.

On top of that, the team notes that many microscale silicon products still utilize nanoparticles as resources. These nanoparticles are not practical for large-scale production. So scientists remain to look for simple and eco-friendly ways to accomplish the application of low-priced production silicon-based materials in lithium-ion batteries.

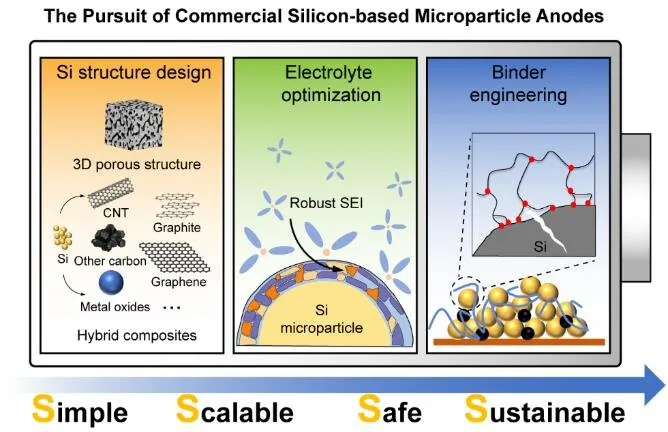

As they take into consideration the leads of future commercialization of silicon-based anodes, they note that maintaining the electrode framework integrity to ensure stable cycling performance is of vital importance when utilizing over low-grade silicon-based materials as the silicon resources. While the mix of porous silicon microparticles and hybrid composites has actually been researched thoroughly, not as much research study has been done related to failure mechanism analysis of created micro-sized silicon.

The team notes that binder products, that hold together the active material particles within the battery's electrode, play a vital role in maintaining structural honesty. They recommend that establishing a multifunctional polymer binder with self-healing and carrying out properties would certainly aid to improve the mechanical stamina of the electrodes and to build an extensive conductive network. With their high architectural advantages, naturally obtained polymers should have better success in this role.

"Silicon holds great possible as an anode material for high-energy-density lithium-ion batteries. Constructing extremely stable silicon microparticle electrodes from the perspective of easy, scalable, risk-free, and lasting technology is difficult and significant," said Hu.

Looking in advance, the team notes that the failure mechanism analysis of developed micro-sized silicon is still lacking based upon multi-scale and multi-physical fields. Researchers require to establish in-situ analysis methods to make clear the relationship in between the style approach and electrode performance.

For example, the result of pore distribution on stress dispersion, the development of active particle frameworks, and the dependancy of surface chemistry and electrical area distribution on carbon adjustment call for a comprehensive understanding. They propose that the development of simple, green, effective, controllable, and energy-saving synthesis technology is crucial to meeting the requirements of commercial production.

"We anticipate to realize the application of low-cost silicon-based materials in full cells through electrode material style, electrolyte optimization, and binder development by a simple and eco-friendly course," stated Hu.

Also read

- Pace Digitek switches on 2.5-GWh battery-storage plant in Karnataka

- CATL-led Indonesia Battery Integration Project breaks ground—US $6 billion for a full value-chain hub

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record

- EDF Acquires 500-MW Gate Burton Solar Project from Low Carbon