RENA picks up 15 GW devices order

- Germany based PV tools distributor RENA Technologies has actually gotten what it calls its 'largest ever order', from a tier 1 supplier in Asia, for 15 GW of its wafer texturing tools. Financial details of the deal have not been divulged, although the business states that the order is worth "tens of numerous euros."

The solar industry's largest producers are proceeding with enthusiastic development strategies, indicating that they see little factor to stress concerning long term demand for PV modules. As well as major gamers remain to invest in PERC production, suggesting the technology will remain to be the mainstream in manufacturing for numerous years yet.

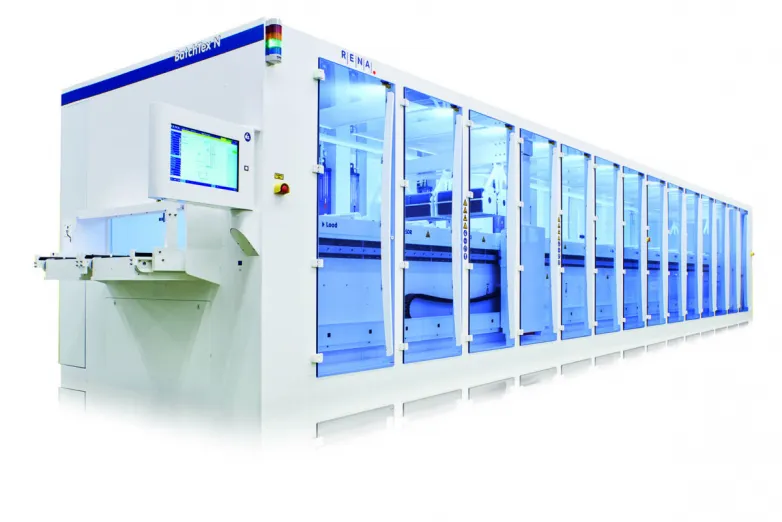

The latest proof for these fads can be found in the type of a 15 GW order worth tens of millions of euro for wafer texturing devices generated by German supplier RENA Technologies. The order, positioned by an unrevealed tier-one supplier, is for two of RENA's wet chemical handling platforms-- BatchTex XL as well as InOxside Fusion-- both used in the cleaning and also prep work of wafer surface areas for cell manufacturing processes.

" We are implementing incredibly cutting-edge technology which has been developed by our teams in Germany as well as China in record time," stated RENA CEO Peter Schneidewind. "We are delighted that the innovative toughness of RENA and the dependability of our systems are valued by our client."

Price down

Both platforms, according to RENA, will offer to lower manufacturing prices for the client, with the InOxside Fusion claimed to utilize dramatically much less nitric acid than its competitors' tools. The tools will refine wafers as much as 210mm-- which currently appears to a well established fad among suppliers. "The fairly space-saving option uses our customer huge possible savings and also collections brand-new requirements in wet chemical processing innovation," included RENA's vice head of state of Sales Ulrich Jäger. "The trend in the direction of M12 [210mm] wafers continues to expand as well as thanks to our makers, we are very well gotten ready for it."

Though lots of European based PV devices providers have battled recently thanks to competition from vendors based in Asia, wafer texturing is just one of a couple of areas in the manufacturing where a European provider has successfully preserved market share.

Talking with pv magazine back in January, Schneidewind kept in mind that it still counts three tier-one makers among its customers, associating the business's success to cutting-edge products and a strong presence in China. And the company further notes that after the SNEC event proceeded in Shanghai last month, it has actually seen significant interest in its remedies from numerous other cell suppliers.

Also read