PV-electrochemical water-splitting for hydrogen production

- A German research study team has developed a brand-new photovoltaic-electrochemical gadget for alkaline water electrolysis. The prototype has a preliminary solar‐to‐hydrogen performance of approximately 7.7%.

Researchers at Germany's Jülich Institute for Energy and also Climate Research (IEK-5) have developed a photovoltaic-- electrochemical (PV-EC) water-splitting device powered by solar power.

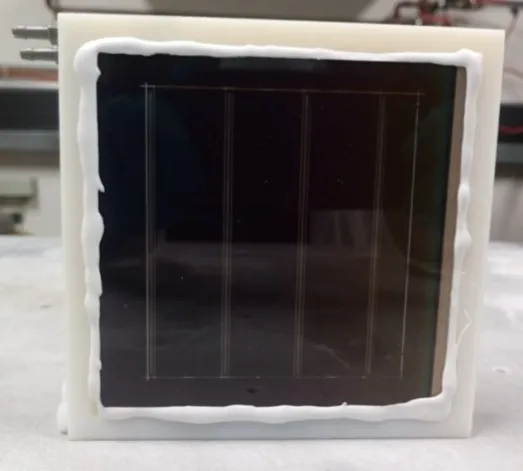

The incorporated PV-EC device with an energetic area of 0.5 cm2 was created with photovoltaic panels based on triple‐junction thin‐film silicon solar batteries with an efficiency score of 10.8% and also an electro-deposited bifunctional nickel iron molybdenum water‐splitting stimulant.

" The introduction of a triple‐junction Si solar battery offers the possibility of manufacturing a self‐contained base unit without the requirement for added series interconnection, which is normally required when using solitary or double‐junction solar batteries," the research study group stated, including that a comparable strategy might also lead to more effective as well as cheaper tools, as dead areas produced by affiliations are avoided. Their performance increases by lowering the dead location and also enhancing their active area.

With an aperture location of 64 cm2 and an energetic area of 56 cm2, the cordless photovoltaic panel is able to provide an open‐circuit voltage of approximately 2.16 V and also a voltage at the maximum power factor of about 1.72 V, which the scientists insurance claim suffices to enable bias‐free water splitting.

When it comes to the water-splitting driver, the scientist established a bifunctional NiFeMo device prepared by electrodeposition.

" The bifunctional catalysts enable the PV-- EC system to eliminate the demand for two various stimulant materials for the anode and also cathode side, which uses the possibility for lower prices of driver manufacturing as well as system setup," the academics described. The gas separation membrane layer, the photovoltaic panels, as well as the stimulants were mounted in a 3D-printed structure.

Contrasted to conventional water‐splitting systems, the new gadget is claimed to have a better light absorbing course, thanks to the superstrate arrangement of the solar cells, without unavoidable losses as a result of the disturbance of drivers and also bubbles. The catalyst is not clear and also it can soak up a few of the light's wavelengths

The PV-EC tool had an initial solar‐to‐hydrogen (STH) effectiveness of about 7.7% and also after 100 hrs of operation this effectiveness come by 17% to 6.40%. "The upscaled prototype gadget with an aperture area of 64 cm2 was discovered to be stable for 30 mins," researcher Minoh Lee told pv magazine. "Although our upscaled gadget has actually shown fairly fast reduction of the STH effectiveness, it is still worth noting that the gas splitting up is first shown in such a bias-free and also wireless tool at large scale."

Lee stated the main factor for the failing is using improper supporting components, such as unsuitable adhesives between the gadget body and back cover glass, as well as the negative layout of the gas splitting up, instead of the deterioration of PV and also the electrocatalyst.

" We expect that the upscaling device can be extra steady if ideal design of gas separation is used and appropriate adhesive is used in the upscaling tool," Lee added. "If that were to happen, it would certainly be feasible to advertise this modern technology quickly."

The researchers go over the gadget in A Bias‐Free, Stand‐Alone, and also Scalable Photovoltaic-- Electrochemical Device for Solar Hydrogen Production, recently released in Advanced Sustainable Systems.

Also read

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record

- Self-Assembling Molecule Breakthrough Brings Commercial Perovskite Solar Closer to Market

- Camphor Additives Boost Perovskite Solar Cell Efficiency

- NUS Sets Record With 26.4% Perovskite-Organic Solar Cell