Perovskites meet the stability standard

- European research group Solliance says its perovskite modules have passed three key industry standard reliability tests: Light soaking, damp heat and thermal cycling. The group said it is the first time perovskite modules of that size have achieved such results and represents a milestone in the technology’s move toward commercialization.

Perovskite PV technology has moved forward in leaps and bounds in recent years, with cell and module efficiencies quickly growing from just a few percent to figures that match and even surpass the performance of commercial silicon and thin-film products.

Though stability has improved at a similar pace – the first perovskite PV cells, fabricated a decade ago lasted only minutes – the issue remains a key concern and one which has prompted caution among manufacturers taking an interest in the technology.

The latest announcement from European solar research organization Solliance, however, could ease stability concerns. Solliance, which incorporates Dutch research organization TNO and Belgian counterpart imec, claims it has put perovskite modules made on its pilot production line through rigorous stability tests and achieved impressive results that would meet industry standards.

Rigorous

“By passing three tortuous aging tests, Solliance and its industrial partners take a major step towards commercialization of this novel solar technology,” read an announcement from the research body. “This will have a major impact on how solar energy can be applied.”

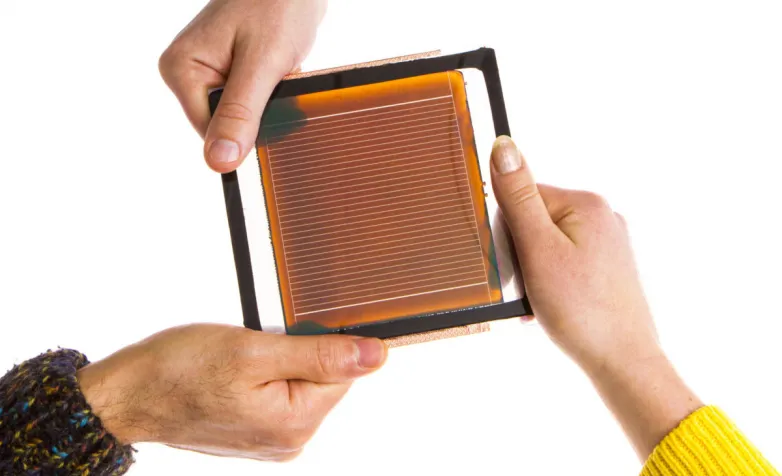

The glass-glass encapsulated modules, measuring 6in by 6in with an aperture area of 100cm², were fabricated using sputter and slot die coating, atomic layer deposition and laser interconnection.

The results

The modules were first subjected to light soak testing – where they were exposed to 1,000 hours of continuous illumination at ‘one sun’ intensity. According to Solliance, performance increased over the first 100 hours before stabilizing.

The next stage was damp-heat – another 1,000-hour test which exposed the modules to 85% humidity at a temperature of 85 degrees Celsius. That was followed by thermal cycling, with the modules subjected to 50 cycles of temperature change, from -40 to 85 degrees Celsius.

The modules came out of the damp heat test with 95% of their initial performance and did not suffer any efficiency loss during thermal cycling, according to Solliance.

The modules tested had an initial aperture area efficiency of “above 10%”, according to Solliance, lower than would likely be needed to stoke serious commercial interest. However, perovskite cells have already achieved far higher efficiencies and combining such performance with stability will be the next step.

“These encouraging results put the perovskite thin-film photovoltaic technology one step closer to commercialization,” said Solliance.

Also read