Next-generation light-weight, flexible and long-lasting batts

- A group of Korean researchers, headed by Prof Soojin Park, has created foldable batts with thin 3D organic electrodes.

Not long ago, a group of Korean scientists has created a monolithic electrode to substitute heavy-weighted collectors made of copper. This is likely to allow making a high-capacity flexible batt.

Prof S.Park, together with a postdoctoral researcher, a PhD student, and KIMS, has created a flexible batt with a thin 3D electrode. The research team has managed to quadruple the batt energy density by making an anode of an organic material instead of graphite. At the same time, the batt weight has been decreased by an order. This has been achieved thanks to a 3D copper collector replacing a traditional collector.

Organic materials are low-conductive, which made integration of organic materials and collectors quite a challenge. That is why, prior to the latest discovery, there was no way to develop a monolithic electrode with an organic material. The Korean scientists have found a new method to substitute low-energy-density anode and heavy collector that are currently used.

The group has developed a high-conductive 3D structure with the help of SWCNT aerogel. They have created a monolithic, thin electrode by means of nanoscale IBN organic materials. The capacity of such a monolithic 3D electrode coated with layers of IBN can reach 1550 milliampere hour, which is sufficient for over 800 recharges.

The organic material the new electrode is coated with maximizes both electrochemical performance of rechargeable batts by fast transfer of Li through active sites and energy density of organic electrodes. Thickness of an organic material layer may be adjusted.

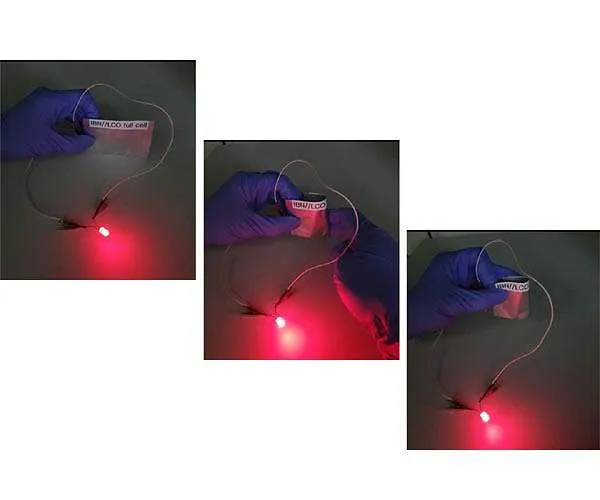

Such innovative electrodes are likely to substitute conventional metal collectors. This will allow making foldable rechargeable batts suitable for e-vehicles, telecom, flexible and portable e-gadgets.

Also read