Next-gen electric lorry batteries: These are the concerns we still need to respond to

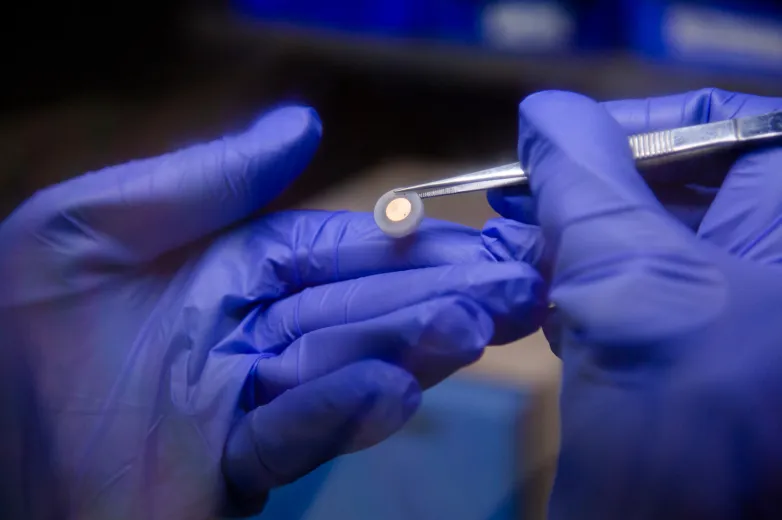

- The future generation of electrical car batteries, with higher range and improved security, could be arising in the form of lithium metal, solid-state modern technology.

However key inquiries about this encouraging power supply require to be addressed before it can make the dive from the laboratory to making facilities, according to University of Michigan scientists. As well as with efforts to bring electrical vehicles to a majority of the population, they state, those questions require responding to swiftly.

Jeff Sakamoto and also Neil Dasgupta, U-M associate teachers of mechanical engineering, have actually been leading researchers on lithium metal, solid-state batteries over the past years. In a point of view item in the journal Joule, Sakamoto as well as Dasgupta set out the primary concerns dealing with the modern technology. To establish the questions, they worked in close partnership with leaders in the auto industry.

Major automakers are going all-in on electric lorries this year, with several announcing strategies to terminate internal-combustion engine autos in the coming years. Lithium-ion batteries made it possible for the earliest EVs and they stay the most usual power supply for the most up to date designs coming off production line.

Those lithium-ion batteries are approaching their peak performance in terms of the EV array on a single fee. And also they come with the need for a heavy as well as cumbersome battery administration system-- without which there is danger of onboard fires. By making use of lithium metal for the battery anode along with a ceramic for the electrolyte, researchers have demonstrated the capacity for doubling EV range for the exact same dimension battery while considerably minimizing the capacity for fires.

" Incredible development ahead of time lithium steel solid-state batteries was transformed the last decade," Sakamoto stated. "However, numerous challenges stay on the path to advertising the modern technology, specifically for EVs."

Inquiries that require to be solutioned to profit from that possible include:

- How can we produce porcelains, which are weak, in the large, paper-thin sheets lithium metal batteries require? Do lithium metal batteries' use of ceramics, which need power to heat them approximately more than 2,000 degrees Fahrenheit during manufacturing, counter their environmental advantages in electrical cars?

- Can both the porcelains and also the process used to manufacture them be adjusted to make up defects, such as breaking, in such a way that does not compel battery makers as well as car manufacturers to dramatically overhaul their operations?

- A lithium steel solid-state battery would not require the hefty and also cumbersome battery management system that lithium-ion batteries need to keep sturdiness and minimize the danger of fire. Exactly how will the decrease in mass and also volume of the battery administration system-- or its removal altogether-- impact efficiency and also durability in a solid-state battery?

- The lithium steel requires to be in continuous contact with the ceramic electrolyte, indicating added equipment is required to apply pressure to maintain call. What will the included equipment mean for battery pack performance?

- Sakamoto, who has his very own startup firm focused on lithium metal solid-state batteries, states the modern technology is having a minute now. Yet the interest driving the moment, he states, should not be successful of itself.

The paper is titled, "Transitioning solid-state batteries from lab to market: connecting electro-chemical mechanics with practical factors to consider."

Also read