New optimizations for a 24.5% efficient heterojunction solar cell

- Scientists in Germany evaluated the major sources of performance loss in a silicon heterojunction cell, as well as developed numerous optimization approaches to improve overall performance.

By including a 2nd layer of amorphous silicon at the rear of the gadget, as well as a magnesium fluoride anti-reflective layer, they had the ability to improve cell efficiency by around 1% to get to 24.51%.

Heterojunction (HJT) is amongst the most encouraging courses to higher performances in silicon PV. While HJT modules are currently in production from a few producers, there is plenty of possible to push their performance higher.

Chinese maker Longi Solar previously this year established a record for HJT cell efficiency at 26.3%, and also Australian start-up SunDrive pressed performance for a commercial-sized to 25.54% back in September. Cell performances for the majority of HJT cells in automation, nevertheless, remain around the 23-24% mark.

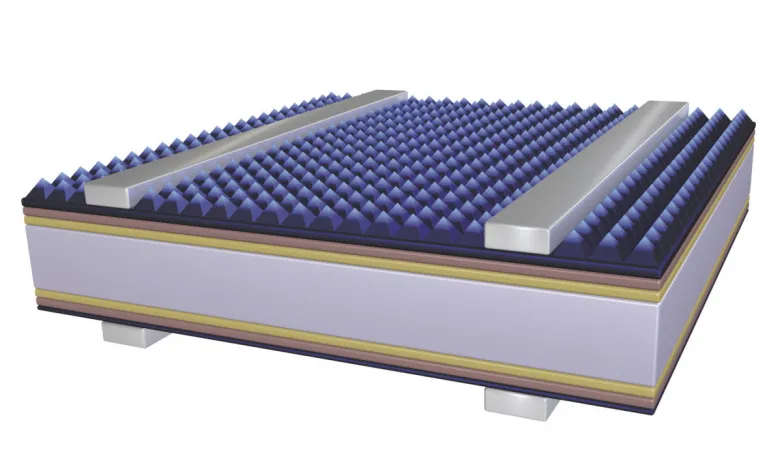

Researchers led by Germany's Forschungszentrum Jülich assessed the systems causing efficiency losses in an HJT cell, and also determined numerous potential brand-new routes to improved effectiveness. And also they had the ability to demonstrate these courses in action, enhancing the efficiency of an M2-sized HJT cell from 23.55% to 24.51% through using a two-layer structure of amorphous silicon as well as the enhancement of magnesium fluoride as an anti-reflective layer. Their job is described completely in the paper A route towards high-efficiency silicon heterojunction solar cells, published underway in Photovoltaics.

Rear side optimizations

The team kept in mind that losses in the cell existing were primarily brought on by representation, light capturing and parasitical absorption, while transport between the silicon layers and also the clear electrode was the source of losses in fill factor. Several usual approaches to minimize parasitical absorption, they note, are in opposition with initiatives to decrease the collection resistance.

In seeking ways to avoid this opposition, the group concentrated on the rear side of the cell. They separated the amorphous silicon layer right into two parts, with a porous first layer as well as a dense 2nd layer. This was revealed to minimize resistance losses in between the layers on the rear side, and also boost the cell's fill factor. Second of all, they applied a layer of magnesium fluoride in between the transparent conductive oxide as well as back reflector, which lowered absorption and boosted the current in the cell.

In their analysis of the loss systems, the team additionally identified several other possible courses to improvement, with opportunities consisting of more clear, vast bandgap window layers, or further optimizations to the transparent conductive oxide layer, taking into account both optical and electric impacts.

Also read