New metallization tech to reduce microcracks in solar cells

- A U.S. research group has developed a metal-carbon-nanotube composite – MetZilla – which can be embedded in commercial, screen-printable silver pastes and is said to reduce the formation of hotspots in solar modules and to prolong panel lifespan. The composite metal contacts are also ‘self-healing’ as they are able to regain electrical continuity after cycles of complete electrical failure caused by extreme strain.

Scientists from the University of New Mexico and the U.S. Air Force Research Laboratory claim to have developed a metallization technique which can be used to reduce electrical losses and hotspots in solar panels and in PV modules used to power spaceflight and UAVs.

For commercial PV modules, the new technology consists of a drop-in replacement, screen-printed metallization system based on multi-walled carbon nanotubes which can be embedded in commercial screen-printable silver paste. The MetZilla Paste Technology is intended to replace traditional contact metallization and is said to considerably reduce the occurrence of hotspots in solar modules, which are caused by microcracks in the cells. The process, which is being developed by start-up Osazda Energy LLC, is said to also prolong the lifespan of modules beyond 30 years.

MetZilla comprises multi-walled carbon nanotubes embedded in the silver matrix to electromechanically reinforce the metal grid lines and busbars of multi-junction solar cells. Its developers claim it has no impact on the electrical properties of the grid lines and busbars. “When the carbon nanotubes are properly functionalized and appropriately incorporated into commercial silver pastes, the resulting metal contacts on solar cells, after screen-printing and firing, show exceptional fracture toughness,” wrote the innovation’s creators in a paper describing the process.

Self-healing composite metal contacts

The resulting composite metal contacts, according to Osazda scientists, have an electrical gap-bridging capability of up to 50 μm and are self-healing as they can regain electrical continuity even after cycles of complete electrical failure under extreme strain.

“The exact mechanism behind this self-healing behavior remains unknown and requires … further study,” stated the developers. “In contrast, the test lines from conventional metallization fail irreversibly upon crack formation and do not regain electrical continuity when the gap is closed.”

The Osazda team claim the low-cost technology can increase module toughness by 16% for screen-printed and fired grid lines. “This increased ductility would presumably increase the lifetime of PV modules against stress-induced substrate cracks, metal line fractures and ultimately hot spots,” said the developers.

The scientists added, initial tests were conducted on mini-modules. For integration into larger devices and commercial production, paste viscosity control and screen printing must be improved, as well as firing to lower the contact resistance between grid fingers and substrate and line resistance.

Space applications

A variation of the technology can also be applied to the high-efficiency gallium arsenide (GaAs) solar cells used in satellites. Metzilla Plate Technology replaces photolithography and vacuum evaporation in the production of III-V material solar cells.

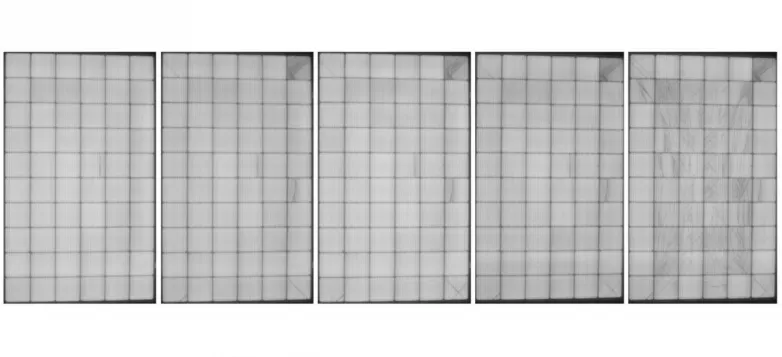

Osazda scientists claim their electroplating process has strong influence over contact patterns and metallization stacks, ensuring cell-fracture durability through the incorporation of the carbon nanotubes. According to the developers, composite-reinforced cells offer better performance than multi-junction devices produced with traditional metallization processes, even when the cell is intentionally cracked.

“Upon the introduction of cracks, the composite-reinforced cells exhibit virtually zero loss in short-circuit current density, while retaining a spatially contiguous electroluminescence,” stated Osazda. Cells made with conventional metallization showed a loss of up to 55% in short-circuit current density.

“As for heterojunction technology, it requires low-temperature metallization,” nanotube creator Sang M Han told pv magazine, “so in that case, MetZilla plate technology, which was originally intended for space PV, would be applicable.”

Also read