Nanostructures for ultrathin flexible wafer

- Researchers in South Korea integrated 2 processes to engrave a nanostructure of little pyramids onto the surface of a silicon wafer. Along with trapping much more light and also enhancing the cell effectiveness, the team declares that its nanostructure improves the mechanical flexibility of the cells. This can potentially enable making use of much thinner silicon wafers than is currently feasible in manufacturing.

Wafers used in cell production today are typically 180-200 microns thick. Going thinner than this is extensively thought to bring about problems with the wafer being also breakable to stand up to the stress and anxieties it is put through both during manufacturing and also in the field. And also because the expense of polysilicon has actually dropped continuously recently, producers do not have a strong reward to minimize consumption.

Amongst researchers though, there is still a lot of interest in 'ultrathin' cells at densities of 50 microns or much less. As well as saving money on polysilicon prices, these can bring about much lighter and also much more flexible cells appropriate for applications past standard PV modules. And also researchers additionally theorize that collaborating with ultrathin wafers can open doors to greater performance success.

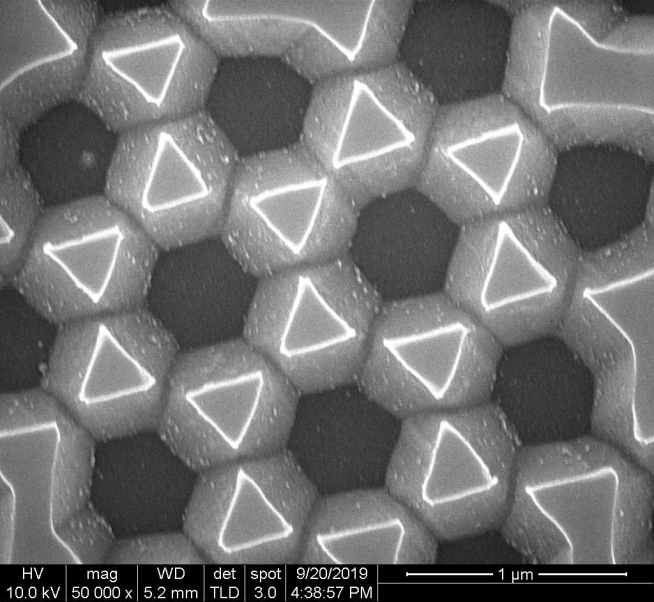

Researchers led by the Korea Institute of Science and Technology (KIST) insurance claim to have found a way to boost the mechanical flexibility of cells 50 microns thick, by engraving a light-trapping nanostructure onto their surface.

Light trapping

Cells in production are typically etched with a pyramid-like structure, which 'catches' more light, stopping it from being shown away from the cell. The team at KIST checked out methods to make this pyramid framework also smaller sized, and also found that they could accomplish results similar to standard procedures, whilst substantially improving the mechanical flexibility of the wafer.

The work is defined in the paper Fabrication of quasi-hexagonal Si nanostructures and also its application for flexible crystalline ultrathin Si solar cells, released in Solar Energy. The team made use of a mixed procedure of nanosphere lithography and wet engraving to fabricate cells with a quasi-hexagonal nanostructure on their surface. Cells etched with the nanostructure had a critical bending distance 46% less than those with standard pyramid etching, and revealed effectiveness around 1% lower.

" The production of slim wafer-based solar cells is extremely difficult because of the delicacy of the slim wafers. Slim wafers with surface splits or appearances are much more vulnerable to breakage due to the fact that the surface area microstructures serve as stress and anxiety focus sites." KIST senior scientist Inho Kim informed pv magazine. "We do not have information regarding damage yield of thin wafers in production. However we can state the damage yield of the thin wafers textured with the nanostructures would certainly be greatly lowered, compared to the conventionally textured (micro-pyramids) wafers."

With further optimizations to its process, the group expects that its approach to nanostructuring could additionally yield far better lead to terms of light capturing and also cell efficiency, in addition to the demonstrated advantages to mechanical flexibility.