Modular systems to generate perovskite-silicon cells on six-inch wafers

- Researchers in Germany are scaling up initiatives to bring perovskite-silicon tandem solar cell innovation into commercial scale manufacturing. The scientists state production cells of that kind is feasible on widely-available six-inch silicon wafers as well as modular systems are being created to do so at scale.

Scientists at German proving ground the Helmholtz-Zentrum Berlin (HZB) are planning to bring perovskite-silicon tandem solar innovation to automation. "Our objective is to enhance the performance of these novel cells to more than 30%-- not just at lab scale but also when generated on a commercial scale," said Bernd Stannowski, head of the Competence Center Photovoltaics Berlin at the HZB.

Stannowski as well as his group are servicing the growth of modular manufacturing to make it possible for the large scale manufacturing of solar cells on six-inch wafers.

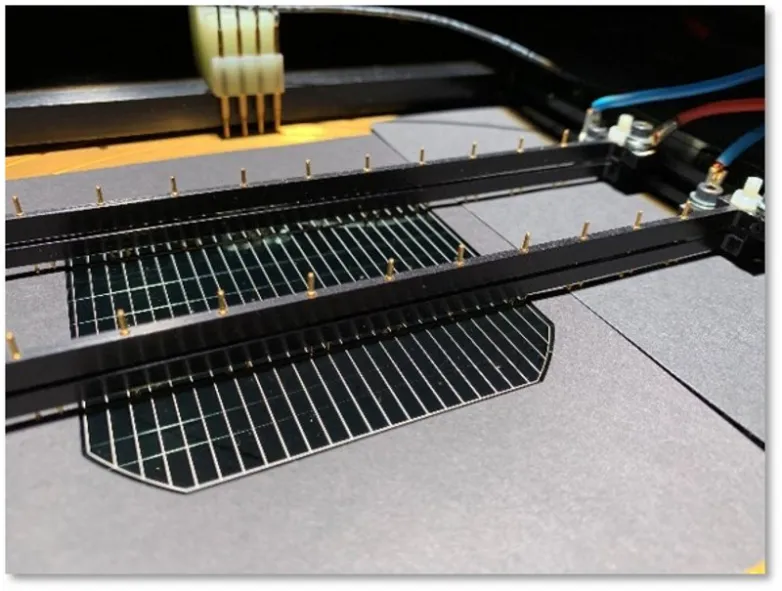

The researchers stated, the silicon heterojunction lower part of the tandem cell requires really thin amorphous-silicon call layers generated utilizing plasma-enhanced chemical vapour deposition (PECVD). The tandem cell developers stated they are checking an option supplied by Swiss company Indeotec, which focuses on the advancement and also construction of PECVD/PVD (physical vapor deposition) systems for pilot manufacturing as well as R&D functions. "As the first system of its kind in the world, it has what is known as PECVD-Mirror process modules, with which silicon wafers can be covered on both sides without needing to turn them," said Stannowski.

For the tandem cell upper layer, the energetic perovskite material, the HZB's Integration & Novel Technologies research laboratory is developing a vacuum deposition system for different materials, to conduct study right into hybrid silicon-perovskite frameworks with the support of German firms Von Ardenne and also Creaphys.

Stannowksi said a newly-ordered facility, of which no additional information were given, is expected to incorporate all the process steps for making the perovskite top cell. He added: "Using this unique innovation, the total cell-- including several layers including the electric get in touches with-- will have the ability to be generated instantly and also at high throughput."

HZB scientists accomplished an effectiveness of 24.16% with a CIGS-perovskite tandem cell in April. That record implied tandem modern technology effectiveness surpassed the 23.35% record for a standalone 1cm ² CIGS cell embed in January last year by Japanese producer Solar Frontier. HZB also holds the efficiency record for a perovskite-on-silicon tandem cell, at 29.15%.

According to current research from France, PV components made with tandem solar cells will need to show effectiveness of 30% and also use the exact same life time and destruction rate as standard crystalline panels if manufacturers want to hit commercial manufacturing. That paper-- which assessed the potential competitiveness of tandem components versus crystalline silicon items-- stated commercial variations of the latter will certainly reach efficiencies of 22-24% this years, and potentially 25% if interdigitated back-contact heterojunction products get to commercial manufacturing.

Also read