MIT, Standford scientists use machine learning for pervoskite solar cell development

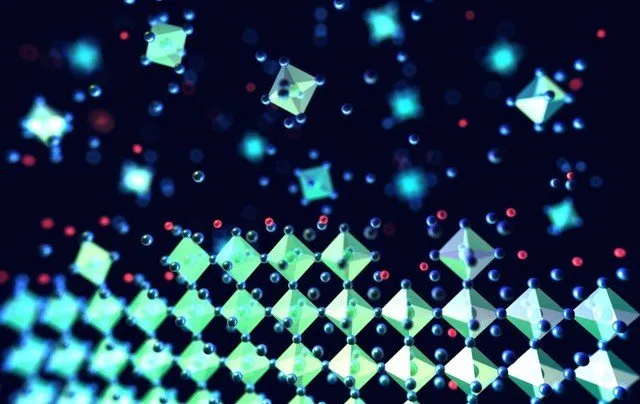

- Perovskites are a team of layered crystalline compounds defined by the configuration of the atoms in their crystal lattice. There are hundreds of such possible compounds as well as various methods of making them.

While the majority of lab-scale development of perovskite materials uses a spin-coating technique, that's not practical for larger-scale production, so business and laboratories all over the world have been looking for ways of converting these laboratory materials into a practical, manufacturable item.

Perovskites are a family of materials that are presently the leading contender to possibly replace today's silicon-based solar photovoltaics. They hold the assurance of panels that are far thinner and lighter, that could be made with ultra-high throughput at room temperature as opposed to at numerous levels, and that are more affordable as well as simpler to carry as well as set up. However bringing these products from controlled lab experiments right into a product that can be manufactured competitively has actually been a lengthy struggle.

Production perovskite-based solar cells includes enhancing at the very least a dozen or two variables simultaneously, even within one particular production technique amongst lots of possibilities. Yet a brand-new system based upon a novel approach to machine learning can accelerate the growth of enhanced manufacturing approaches and also help make the future generation of solar power a truth.

The system, created by scientists at MIT and also Stanford University over the last few years, makes it possible to integrate information from previous experiments, and also details based upon personal observations by seasoned employees, into the machine learning process. This makes the outcomes more precise and also has actually already caused the manufacturing of perovskite cells with an energy conversion effectiveness of 18.5 percent, a competitive degree for today's market.

The study is reported in the journal Joule, in a paper by MIT professor of mechanical design Tonio Buonassisi, Stanford teacher of products scientific research and also design Reinhold Dauskardt, current MIT research assistant Zhe Liu, Stanford doctoral graduate Nicholas Rolston, and also 3 others.

Perovskites are a team of layered crystalline compounds defined by the configuration of the atoms in their crystal lattice. There are thousands of such possible compounds and also various methods of making them. While many lab-scale development of perovskite materials uses a spin-coating technique, that's not practical for larger-scale manufacturing, so companies and laboratories around the world have been looking for ways of translating these lab materials into a practical, manufacturable product.

" There's constantly a big obstacle when you're attempting to take a lab-scale process and then move it to something like a start-up or a manufacturing line," claims Rolston, who is now an assistant teacher at Arizona State University. The team checked out a process that they felt had the best potential, a technique called fast spray plasma processing, or RSPP.

The production process would involve a moving roll-to-roll surface, or collection of sheets, on which the precursor solutions for the perovskite compound would be sprayed or ink-jetted as the sheet rolled by. The material would certainly after that move on to a healing stage, offering a rapid and continual result "with throughputs that are more than for any other photovoltaic technology," Rolston claims.

" The genuine development with this platform is that it would allow us to range in a manner that nothing else product has allowed us to do," he adds. "Also products like silicon require a lot longer timeframe due to the processing that's done. Whereas you can think of [this strategy as more] like spray paint."

Within that process, a minimum of a dozen variables might affect the outcome, a few of them more controllable than others. These include the composition of the starting materials, the temperature level, the humidity, the rate of the processing path, the distance of the nozzle used to spray the material onto a substrate, and also the techniques of curing the product. Most of these factors can communicate with each other, and also if the process is in outdoors, then humidity, for instance, may be unrestrained. Assessing all possible combinations of these variables through testing is difficult, so machine learning was needed to assist guide the experimental process.

Yet while the majority of machine-learning systems use raw information such as measurements of the electrical and also various other properties of test samples, they do not commonly incorporate human experience such as qualitative observations made by the experimenters of the visual and also other properties of the test samples, or details from other experiments reported by other researchers. So, the group discovered a means to incorporate such outside info into the machine discovering model, using a probability variable based on a mathematical technique called Bayesian Optimization.

Using the system, he claims, "having a model that comes from experimental data, we can figure out fads that we weren't able to see in the past." For example, they originally had trouble adjusting for uncontrolled variations in humidity in their ambient setting. However the model revealed them "that we can overcome our humidity challenges by transforming the temperature, for example, and also by altering some of the other knobs."

The system now allows experimenters to much more rapidly guide their process in order to optimize it for an offered set of conditions or needed outcomes. In their experiments, the team concentrated on enhancing the power result, however the system can additionally be used to simultaneously incorporate various other criteria, such as cost as well as toughness-- something members of the team are remaining to service, Buonassisi claims.

The researchers were motivated by the Department of Energy, which sponsored the work, to commercialize the innovation, as well as they're currently concentrating on tech transfer to existing perovskite makers. "We are connecting to business currently," Buonassisi claims, and also the code they created has actually been made easily readily available with an open-source server. "It's now on GitHub, anyone can download it, any individual can run it," he claims. "We more than happy to aid companies get started in using our code."

Currently, several firms are preparing to generate perovskite-based photovoltaic panels, although they are still working out the information of just how to generate them, claims Liu, that is now at the Northwestern Polytechnical University in Xi'an, China. He claims business there are not yet doing large-scale manufacturing, however rather starting with smaller, high-value applications such as building-integrated solar tiles where appearance is essential. 3 of these firms "get on track or are being pressed by financiers to make 1 meter by 2-meter rectangular modules [equivalent to today's most common photovoltaic panels], within two years," he says.

'The problem is, they do not have an agreement on what manufacturing innovation to use," Liu states. The RSPP technique, developed at Stanford, "still has a good chance" to be competitive, he says. As well as the machine learning system the group created might show to be important in guiding the optimization of whatever process winds up being used.

"The main goal was to speed up the process, so it called for less time, much less experiments, and less human hrs to develop something that is usable right now, free of cost, for sector," he says.

Also read