Making Solar Hydrogen with a Side of Carbon Nanotubes

- Two groups of solar researchers have actually established an unique solar activator and also thermochemical procedure for making solar hydrogen that can produce on top of that carbon black and also graphite along with carbon nanotubes. Persuading a six-year duration, the teams first created the details solar reactor, and then ultimately, the thermochemistry for the (license pending) unique methane splitting solar hydrogen procedure.

Research study thermo-chemists Hiroyuki Kimura and Satoshi Seo at the Heat & Fluid Dynamics Research Department at the IHI Corporation in Japan collaborated with the French solar themo-chemistry research team headed by Stéphane Abanades at the French National Centre for Scientific Study (PROMES-CNRS) in establishing the model and the procedure in the Odeillo solar heating system.

Meeting Japan's vision of a hydrogen-based energy system

The IHI Company is amongst several big entities functioning in the direction of the "World's First Hydrogen Society" recommended by Japan's government. The Hydrogen Society pictures sustainable hydrogen to power a lot of the infrastructure currently reliant on nonrenewable fuel sources. Japan's federal government has actually invested 1.5 billion in R&D support to create this future market.

The company grew as a manufacturer of gas generators, jet engines, central heating boilers and turbochargers, as well as is well positioned to manufacture the machinery for tidy energy such as solar thermochemical activators utilized to make solar hydrogen.

" The Japanese government's plan for future hydrogen society has actually been very significant to our firm's strategy on the advancement of modern technology as well as business for contributing to the understanding of social sustainability by purchasing our study to open up a new organisation possibility to add to society's long-lasting sustainability," claimed Kimura.

The suggestion of the Hydrogen Culture is to generate solar hydrogen in the world's big sunny areas like Australia with solar thermochemical reactors, and also to ship the absolutely no discharges solar fuel to Japan and internationally.

" Australia has huge resources of both solar and gas. And additionally other nations from MENA (Middle East and North Africa) are possible. Nevertheless tiny decentralized systems can be installed in several other locations where solar DNI is adequate," he claimed.

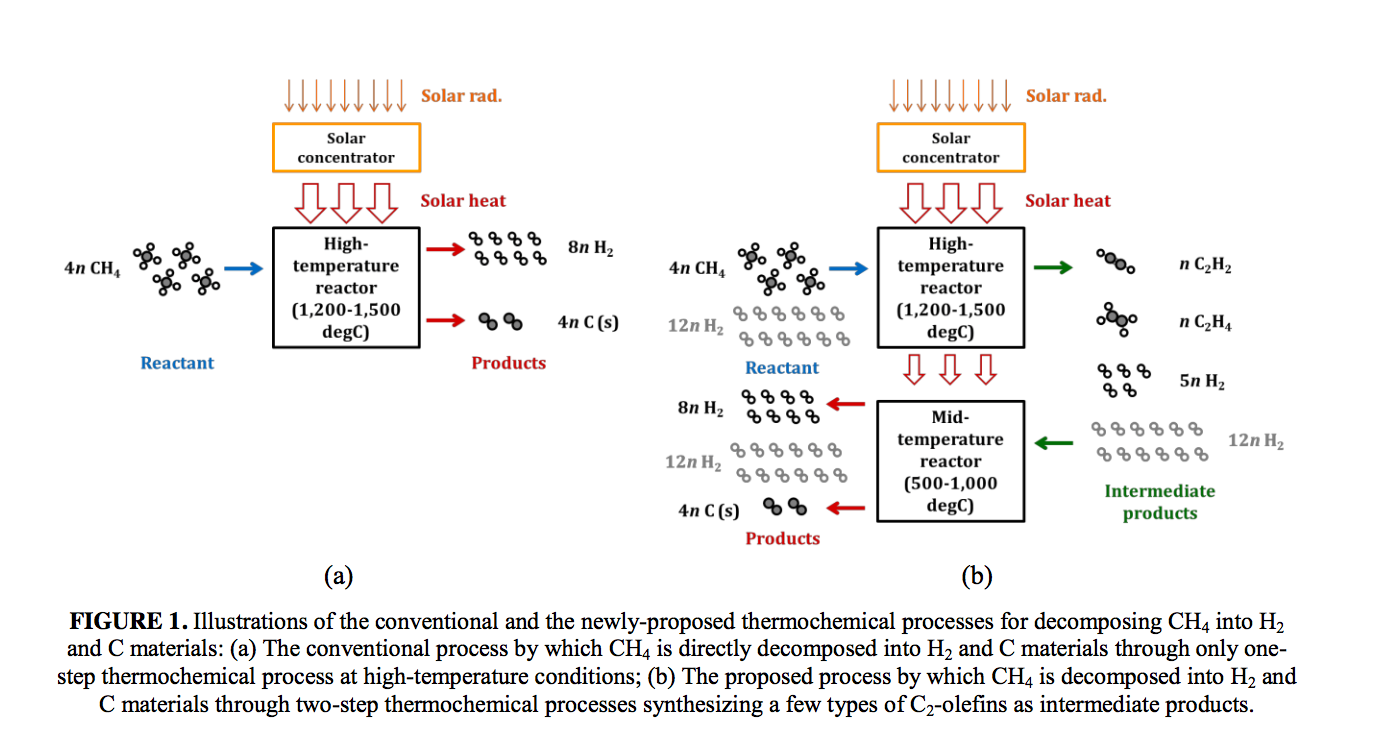

Sector experience aids establish a novel solar activator

With the procedure confirmed at the study degree, Kimura's team plans to create a small-scale two-step solar activator model as well as launch it onto the marketplace so customers can try it and also offer feedback to aid improve as well as boost both the solar activator and the procedure. "At this moment, we are trying to find such customers as companions," Kimura claimed.

He stated that his company would certainly make the solar reactor to make solar hydrogen once the team can locate a method to make it cost effective. This market-driven approach notifies their study.

" So, we need to suggest and create a cost-effective business which can create not only hydrogen as a gas yet additionally high-value marketable carbons as industrial products with solar thermal activator," he noted.

Compared to today's fossil fuel hydrogen, solar hydrogen is still mostly at the R&D stage and remains a lot more costly. Yet one means to counter the cost of its production is to provide beneficial by-products in addition to the solar hydrogen. This is the approach that Kimura as well as Abanades take.

Making solar hydrogen marketable

" The price for the two-step process will certainly be a lot more pricey than the typical solar reforming," clarified Kimura." Nevertheless, this two-step process has a benefit. That is to generate high-value carbon materials such as carbon nanotubes as results instead of CARBON DIOXIDE that the reforming process generates. We have actually estimated that the carbon products can surpass such extra cost."

Carbon fiber nanotubes decrease fuel usage in transportation since by weight this product is much more powerful and stiffer than metal. Carbon nanotubes are additionally utilized in the electrodes of fuel cells. Carbon black is used in tires, inks, rubbers, and also carbon graphite to make synthetic rubies. He acknowledged that-- at the very least in today's market-- the need for carbon materials is a couple of orders of magnitude lower than for hydrogen. Yet as the globe relocates towards minimizing carbon exhausts over the next years this market is likely to increase as even more trains, trucks, ships and airplanes are created from lighter and more powerful carbon fiber.

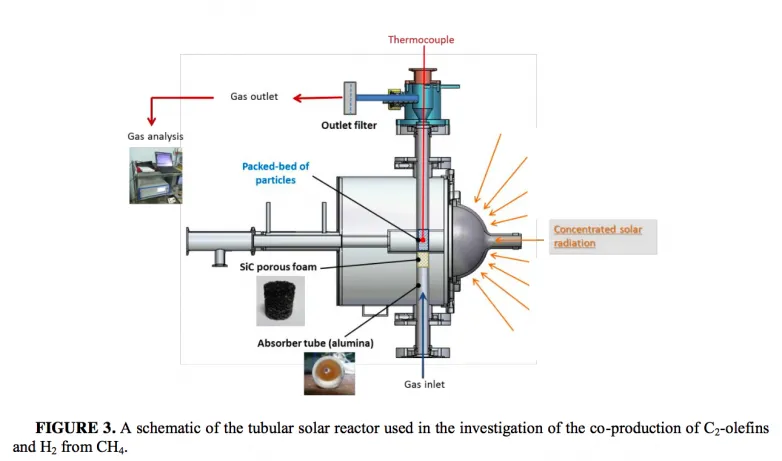

Inventing their 2 step process

As described in the paper co-authored by IHI Firm researcher Satoshi Seo (Manufacturing of C2-olefins and Hydrogen from Methane Pyrolysis with Concentrated Solar power) offered at the SolarPACES Meeting in South Korea; this unique two-step procedure creates hydrogen as well as carbon products without producing carbon dioxide, and also stays clear of several technological issues connected with the conventional direct thermal methane decomposition process.

" When we performed the solar experiments to investigate the standard thermal disintegration of methane at the temperature levels from 1,300 ° C to 1,500 ° C in 2013 and also 2014, we observed that really small amounts of acetylene, ethylene, and also ethane were produced in addition to hydrogen as well as carbon as the items of thermal decay of methane. This searching for from such experiences in the past solar experiments came to be a key-- a chance to devise, propose, as well as attempt the originality," Kimura said.

In the primary step, the solar field is utilized to directly heat up a thermochemical as well as a thermo-catalytic conversion procedure in their solar activator to decompose methane (CH4) right into hydrogen (H2), acetylene (C2H2) and also ethylene (C2H4).

In the 2nd action, carbon nanotubes are created by disintegrating both produced acetylene and also ethylene and stayed methane at a reduced temperature of under 1,000 ° C, externally of iron, nickel or palladium drivers. The return of carbon nanotubes is increased by utilizing this unsaturated acetylene and also ethylene from the primary step as added carbon sources.

" One benefit of the two-step procedure is to be able to expand the yield of nanotubes, which can be enhanced by utilizing acetylene and ethylene as additional carbon resources along with the methane as the main carbon resource," claimed Kimura.

" This process can improve the yield of valuable carbon nanotubes compared to the conventional one-step process for producing carbon nanotubes from methane with metal drivers."

Problems prevented, as well as challenges ahead

There are two ways the process is novel, the particular two-step thermochemistry itself, as well as the quick home heating and also quick cooling of methane in the tube, which improves the production of carbon black, graphite and also carbon nanotubes.

"We integrate two traditional essential processes for generating hydrogen and also different carbon materials from methane without creating carbon dioxide, for the objective of staying clear of a few technological problems of the traditional process of direct thermal decay of methane," stated Kimura.

The most crucial of these stayed clear of technological troubles is that at the high temperatures (of over 1,300 ° C commonly used in solar hydrogen thermochemistry) carbon down payments can comply with the reactor wall surfaces; lowering reliable procedure of a solar reactor.

Kimura as well as co-authors Seo and Abanades designed a procedure that operates at a reduced temperature in the 2nd step, listed below 1,000 ° C, so the carbon sticks to the stimulant rather. The intermediate formation of aeriform C2-hyodrocarbons (C2H2 and C2H4) assists inhibit the blockage of the reactor tube.

"The carbon down payments just on the surface of the catalyst at the mid-temperature (less than 1,000 ° C) in the second step. No thermal decomposition of methane, acetylene, and ethylene takes place at such temperature level, however catalytic decomposition occurs," Kimura discussed.

The procedure is not without its obstacles: Due to the extra injection of hydrogen recycled at the same time, the amount of solar power required to reach the temperatures is somewhat boosted as well as the solar activator style has actually included complexity.

Also read

- RAG Austria’s 100-MW Hydrogen Project Gains EU PCI Status

- Africa’s Green Minerals Fuel Solar Growth While Value Leaves the Continent

- Shell locks green power for Germany’s Refhyne II hydrogen electrolyser

- Bosch Starts 2.5MW Electrolyzer, Meets EU Hydrogen Rules

- Spain sets demand-led grid plan prioritizing hydrogen, renewables by 2030