Making green hydrogen via the exposure of nanomaterials to sunlight

- A research team from the Institut National de la Recherche Scientifique (INRS) has actually joined forces with French researchers from the Institute of Chemistry and also Processes for Energy, Environment and Health (ICPEES), a CNRS-University of Strasbourg joint research laboratory, to pave the way towards the production of green hydrogen.

This global group has actually established new sunlight-photosensitive-nanostructured electrodes. The outcomes of their research were released in the November 2020 problem of the journal of Solar Energy Materials and Solar Cells.

A power transition vector

Hydrogen is being thought about by numerous countries of the Organization for Economic Co-operation and also Development (OECD) as a principal in the transition towards decarbonized sectors as well as markets. According to the INRS Professor My Ali El Khakani, Quebec might strategically place itself in this energy industry of the future. "Thanks to high-performance nanomaterials, we can improve the efficiency of water dissociation to generate hydrogen. This "clean" fuel is becoming increasingly vital for the decarbonisation of the heavy-duty trucking as well as mass transit. As an example, buses utilizing hydrogen as a fuel are currently in operation in a number of European nations and also in China. These buses discharge water instead of greenhouse gases," added the physicist and also nanomaterials professional.

Splitting water particles into oxygen and also hydrogen has long been done by electrolysis. However, commercial electrolyzers are really energy-intensive as well as need big financial investments. The INRS and ICPEES researchers were instead inspired by a natural system: photosynthesis. Indeed, they have created specifically crafted as well as structured electrodes that divided water particles under the sun's light. This is a process known as photocatalysis.

Difficulties in the design and also fabrication of the nanostructured electrodes

For optimal use of solar power, the research groups have actually chosen a really plentiful and also chemically secure product: titanium dioxide (TiO2). TiO2 is a semiconductor understood for being photosensitive to UV-light, which accounts just for 5% of the solar irradiance. Scientists have actually utilized their knowledge in the field to initial change the atomic make-up of TiO2 as well as extend its photosensitivity to visible light. They were able to create electrodes that can absorb up to 50% of the light emitted by the sunlight. A substantial gain right from the beginning!

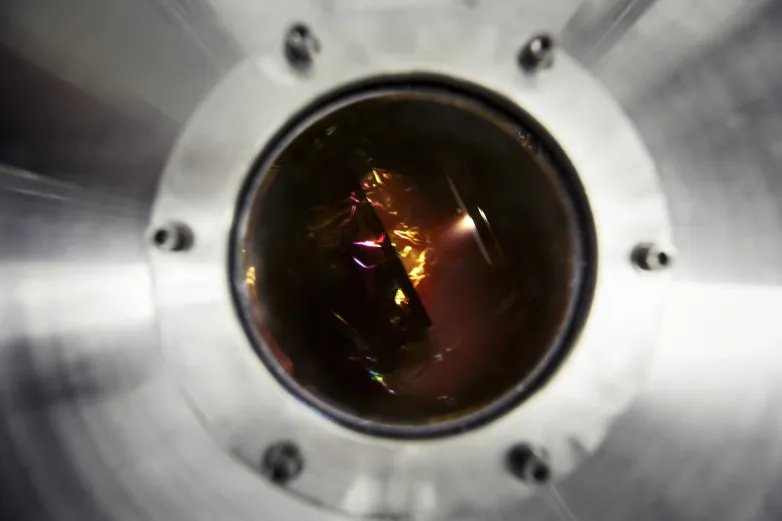

The researchers have actually after that proceeded with the nanostructuration of the electrode to create a network of TiO2 nanotubes that appears like a beehive-like structure. This method increased the reliable surface area of the electrode by an aspect of 100,000 or even more. "Nanostructuring makes best use of the proportion between surface area and volume of a material. As an example, TiO2 nanostructures can use a surface area of as much as 50 m2 per gram. That's the area of a mid-size flat!" Professor El Khakani pointed out.

Challenges in the layout as well as fabrication of the nanostructured electrodes

For optimal use of solar energy, the research groups have selected a very bountiful as well as chemically steady material: titanium dioxide (TiO2). TiO2 is a semiconductor known for being photosensitive to UV-light, which accounts only for 5% of the solar irradiance. Scientists have actually used their proficiency in the field to very first adjustment the atomic composition of TiO2 as well as prolong its photosensitivity to visible light. They had the ability to generate electrodes that can absorb approximately 50% of the light discharged by the sunlight. A substantial gain right from the start!

The researchers have actually after that waged the nanostructuration of the electrode to create a network of TiO2 nanotubes that appears like a beehive-like structure. This technique multiplied the efficient area of the electrode by an aspect of 100,000 or more. "Nanostructuring takes full advantage of the proportion in between surface and volume of a material. For instance, TiO2 nanostructures can provide a surface of approximately 50 m2 per gram. That's the surface area of a mid-size flat!" Professor El Khakani mentioned.

Also read