Incorporating tension as well as temperature level sensing units in crystalline silicon cells

- Fraunhofer ISE scientists have actually incorporated stress and anxiety as well as temperature level sensing units within a PV module. They assert that the gadgets cover an extremely marginal part of the cells, which their communication with the cell as well as the module itself is rather minimal. The sensing units can be produced as part of a normal cell production procedure.

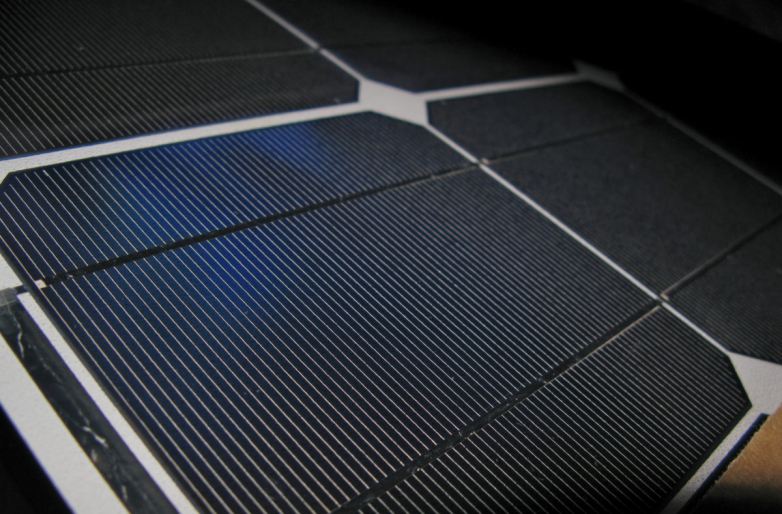

A research study group from Germany's Fraunhofer Institute for Solar Energy Systems ISE are establishing methods to incorporate stress and anxiety as well as temperature level sensing units right into crystalline solar battery wafers, in order to attain constant as well as straight dimension in traditional PV module arrangements.

The researchers discussed that the examined sensing units cover an extremely marginal part of the cell, which their communication with the cell as well as the module itself is fairly restricted. The sensing units can be created via a routine solar battery production procedure, they declared, as well as can be related to both the front as well as rear ends of the cells.

" Also, existing solar battery assembly line could be customized for the sensing unit execution," they wrote in Silicon solar battery-- incorporated stress and anxiety and also temperature level sensing units for photovoltaic components, released underway in Photovoltaics.

The research study group stated that the stress and anxiety sensing unit is piezoresistive, which suggests that it has the ability to react to on the surface caused mechanical stress and anxiety via modifications in its electric resistance. The gadget was put on drift area solar battery wafers constructed from p‐type monocrystalline silicon. "The anxiety sensing unit is recognized as a rectangle-shaped piezoresistive resistor making use of high regional n‐doping by ion implantation as well as succeeding silver metallization," the scientists claimed.

The sensing unit was laminated flooring making use of a standard PV module configuration, with a 14.7 × 10.5 cm2 as well as 1‐mm slim glass, ethyl plastic acetate (EVA) movie, and also a Tedlar Polyester Tedlar (TPT) backsheet.

The procedure to install the temperature level sensing unit adhered to the exact same procedures for the metallization that were taken on for the anxiety sensing unit. The scientists specified the procedure as typical technique for the get in touch with development of high‐efficiency solar cells.

The combination of the sensing units was evaluated with 6 various styles. "All layouts solve the anxiety in the examination samplings and also have level of sensitivities in the variety in between − 45 as well as − 65%/ grade point average (GPA)," the researchers mentioned. "The module combination of this layout reveals that the sensing units can determining the anxiety in laminated solar cells."

The laminated sensing units revealed great security in 145 temperature level cycles from − 35 ° C to +85 ° C, the study group claimed. They included that the tools are just being utilized for R&D functions, which the course to commercialization will certainly need additional research study.