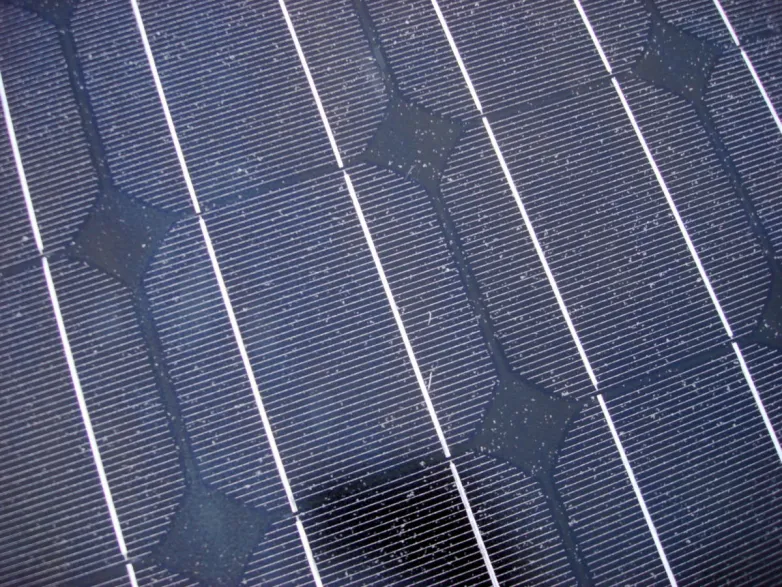

IBC solar cell with 25.0% performance

- Australian researchers have exposed a new cell that improves an earlier gadget with 24.4% performance. They accomplished this 0.6% boost in performance by applying an oxide-nitride-oxide passivation pile, maximizing the diffusion and call area fraction, as well as enhancing texturing with monoTEX surfactant.

Scientists from Australia's University of Tasmania and the Australian National University have developed an interdigitated back-contact solar (IBC) cell with an efficiency of 25.0% and fill variable of 81.0%.

They provided their searchings for in "Excellent ONO passivation on phosphorus and boron diffusion demonstrating a 25% efficient IBC solar cell," recently published in Progress in Photovoltaics. The cell is a development of a tool with a 24.4% efficiency that they created in previous researches.

The academics assert to have actually accomplished the 0.6% increase in performance via an improvement of the manufacturing process, with a particular concentrate on three essential variables. They implemented an oxide-nitride-oxide (ONO) passivation pile, optimized the diffusion and contact area fraction, and also improved texturing with monoTEX surfactant. The latter process entails a regulating as well as wetting representative for alkaline texturing, which is known to simplify the texturing of wafers, expand the texturing procedure window, and increase texturing bath lifetime.

The wafers with symmetrical ONO heaps were corona billed on both the front as well as rear surface areas with a standard configuration. Corona discharge is a method routinely used to down payment favorable or adverse charge externally of materials. It is typically embraced in study to identify the electrical homes of silicon-dielectric user interface.

" The ONO pile on phosphorus diffused wafers was subjected to corona billing at 5.5 kV for 120 s, whereas boron diffused wafers were negatively billed at − 6 kV for 100 s," the academics discussed. "Notably, the surface area passivation is additionally boosted after corona billing."

The researchers performed the post-oxidation annealing (POA) of the thermal silicon oxide layer immediately after the first thermal oxidation, in order to analyze the result of the surface-doping concentration on the effectiveness of the general ONO passivation top quality. They explained that this operation was carried out in an inert gas ambient, which allows the redistribution of dopants, potentially removing the sudden pile-up and also exhaustion at the silicon-silicon oxide (Si/SiO2) user interface.

" In summary, the vital impact of the monitorings in this area is that it nullifies the prejudgment for the requirement of a POA in inert ambient to attain top quality passivation for diffused surface areas," the team said.

The scientists also evaluated the impact of plasma-enhanced chemical vapor deposition (PECVD) for silicon nitride movie on the passivation top quality of both phosphorus and boron-diffused surfaces. This evaluation confirmed that additional corona billing is very beneficial to the surface area passivation of both diffused wafers. The Australian team additionally observed the impact of the thermal silicon oxide density on both the optical residential or commercial properties and the surface area passivation of various surfaces of the cell.

Additionally, the academics used boron-rich layer (BRL) gettering to enhance the last bulk life time within the IBC cell. This action was executed before ONO passivation growth.

" The typical mass life time across six finished cell wafers before metallisation was roughly 46 ms," they clarified. "Such high bulk life-times were not observed in previous cell manufacture sets."

The cell performance was gauged at Australia's Scientific and also Industrial Research Organization (CSIR). Checking has actually already revealed that the tool has an open-circuit voltage of 716 millivolt and a short-circuit current thickness of 43.0 milliampere per cm − 2.

Also read