How to Assemble PCB Board: Everything You Need to Know to Get Started

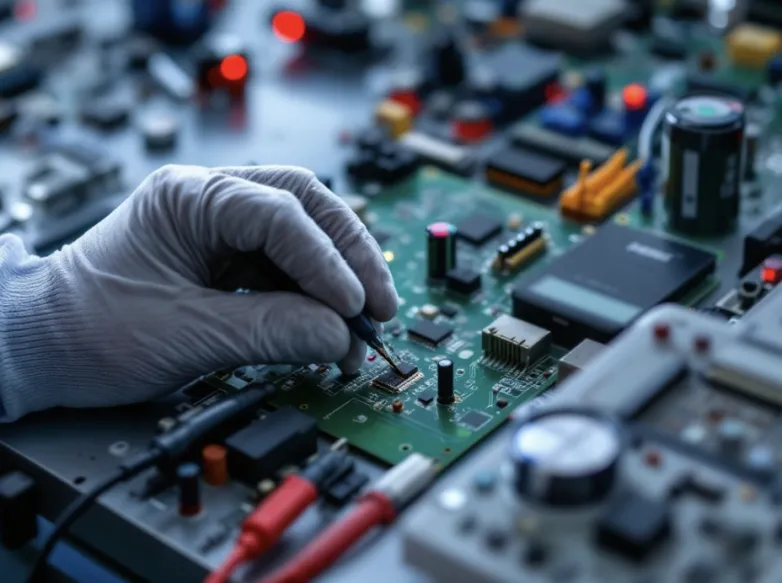

Printed Circuit Board (PCB) assembly is a crucial process in electronic manufacturing, enabling the functionality of various devices. Whether you’re a hobbyist or a professional, learning how to assemble a PCB correctly ensures efficiency, reliability, and longevity in electronic projects. This guide will take you through the entire process of PCB assembly, from preparation to final testing.

PCBs serve as the foundation of most electronic devices, providing a platform where components interconnect to form circuits. The assembly process involves placing components, soldering them onto the board, and conducting inspections and testing to verify functionality. By understanding and mastering PCB assembly, you can create efficient, high-performing electronic circuits for various applications, including consumer electronics, industrial systems, and prototype development.

This guide is designed for beginners and experienced individuals alike, providing step-by-step instructions, essential tools, and troubleshooting tips to ensure a successful PCB assembly. Whether you are working on a simple DIY project or a complex circuit, following these best practices will help you avoid common pitfalls and achieve professional-quality results.

Understanding PCB Assembly

PCB assembly (PCBA) refers to the process of soldering and integrating components onto a printed circuit board to form a functional electronic circuit. This process can be manual or automated, depending on the complexity and volume of production. The two primary soldering methods used in PCB assembly are:

-

Through-Hole Technology (THT): Components have leads inserted into drilled holes and are soldered onto the board.

-

Surface Mount Technology (SMT): Components are placed directly onto the board's surface and soldered using reflow soldering.

Tools and Materials Required

To assemble a PCB, you’ll need the following tools and materials:

-

PCB board (pre-designed and fabricated)

-

Electronic components (resistors, capacitors, ICs, diodes, etc.)

-

Soldering iron (for manual soldering)

-

Solder wire

-

Flux pen or paste (enhances solder flow)

-

Tweezers (for handling small components)

-

Multimeter (for testing continuity and voltage)

-

Soldering station (if using advanced methods)

-

Desoldering pump or braid (for correcting mistakes)

-

Stencil and solder paste (for SMT assembly)

Steps to Assemble a PCB Board

-

Preparing the PCB Board

Before starting, ensure the PCB board is clean and free from dust and debris. Inspect the board for any manufacturing defects such as incorrect traces, missing pads, or misaligned holes. Clean the board using isopropyl alcohol and a lint-free cloth to remove contaminants. Finally, identify component placements by referring to the circuit diagram and PCB layout to ensure proper assembly.

-

Placing Components on the PCB

For through-hole components, insert the leads into the designated holes and bend them slightly to keep them in place, arranging them from lowest profile (resistors) to tallest (connectors). For surface mount components, apply solder paste to the pads using a stencil, use tweezers to place the components onto their respective pads, and check alignment with a magnifying glass before proceeding to soldering.

-

Soldering the Components

For manual soldering of through-hole components, heat the soldering iron to around 350°C, touch the iron to the joint between the pad and the component lead, apply solder wire to the heated joint, and let it flow naturally before removing the solder wire and iron. In reflow soldering for surface mount components, preheat the PCB for even temperature distribution, place it in a reflow oven or use a hot air gun to melt the solder paste, ensuring proper bonding before allowing the board to cool.

-

Inspecting and Testing the PCB

Perform a visual inspection to check for solder bridges, cold joints, and proper component orientation. Use a multimeter for electrical testing, conducting continuity tests to verify all expected connections are intact and measuring voltage at key points to confirm circuit operation. Finally, power up the PCB and test its designed function to ensure it operates as intended before deployment.

Common Mistakes and Troubleshooting

Even with careful planning and execution, errors can occur during the PCB assembly process. Identifying and addressing these issues early can save time and prevent costly rework. Below are some of the most common mistakes encountered and how to troubleshoot them effectively.

Common Mistakes

-

Misaligned components: Ensure proper orientation before soldering, as improper alignment can lead to functionality issues or difficulty in inserting the board into its housing.

-

Cold solder joints: Reheat and apply more solder if necessary, as weak joints can result in poor conductivity and intermittent circuit failures.

-

Solder bridges: Use desoldering braid to remove excess solder, since unintended connections between pads can cause short circuits and render the circuit inoperable.

-

Incorrect component placement: Double-check the circuit diagram before soldering, as placing components in the wrong position can lead to malfunctioning circuits and potential component damage.

Troubleshooting Steps

-

If the circuit doesn’t work: Check for incorrect wiring or loose connections, ensuring all components are properly soldered and oriented according to the circuit design.

-

If there is short-circuiting: Inspect for unintended solder bridges, misplaced conductive materials, or incorrect polarity in components that might be causing a direct connection.

-

If a component overheats: Verify correct polarity and resistance values, as excessive heat may indicate incorrect placement, excessive current draw, or a faulty component.

Choosing a Reliable Printed Circuit Board Assembly Manufacturer

While assembling a PCB manually is feasible for small projects, larger-scale production often requires the expertise of a printed circuit board assembly manufacturer. These manufacturers provide professional assembly services using automated equipment to ensure precision, efficiency, and high-quality results. Outsourcing PCB assembly can help businesses and engineers save time, reduce errors, and enhance product performance.

When selecting a PCB assembly manufacturer, consider factors such as:

-

Experience and Reputation: Look for manufacturers with a proven track record in the industry.

-

Certifications and Compliance: Ensure they meet industry standards such as IPC, ISO, and RoHS compliance.

-

Production Capabilities: Assess whether they can handle your project’s complexity, volume, and technology requirements.

-

Turnaround Time and Cost: Compare pricing and lead times to ensure they align with your budget and timeline.

Conclusion

Assembling a PCB board requires careful planning, patience, and attention to detail. By following the steps outlined in this guide, you can successfully create functional electronic circuits. Whether you’re a beginner or an experienced electronics enthusiast, mastering PCB assembly is a valuable skill that enables innovation and creativity in electronics design.

Beyond the technical aspects, PCB assembly plays a crucial role in advancing technology and enhancing various industries, from telecommunications to medical devices. A well-assembled PCB ensures not only functionality but also reliability and durability, contributing to the efficiency of modern electronic devices.

With practice and adherence to best practices, you can refine your skills and develop high-quality PCBs for both personal and commercial use. So, gather your tools, start experimenting, and enjoy the rewarding process of bringing electronic designs to life.

Also read

- The Rapid Evolution of Direct Current Fast Charging for Electric Vehicle Fleets

- Scaling Data-Driven Campaigns Without Breaking Your Stack

- The 12th World Sustainability Forum (WSF-12)

- The Hidden Electrical Upgrades You Need Before Going Solar in the North Bay

- How Solar-Powered Valve Automation Enhances Standpipe System Performance