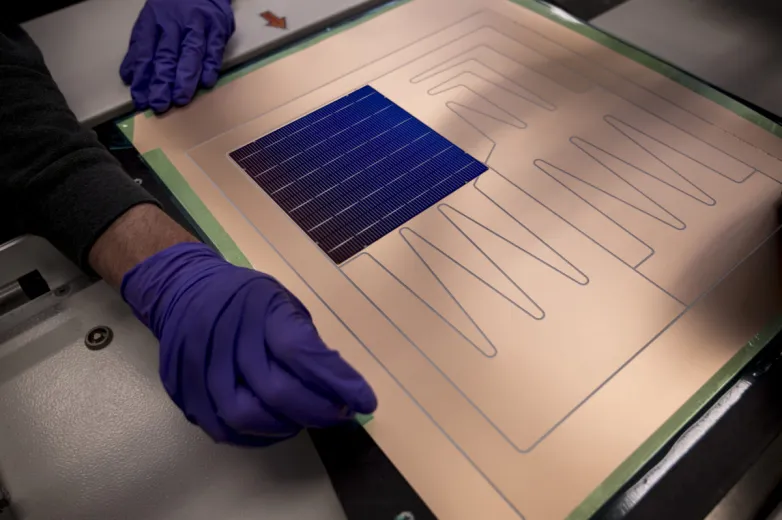

Heterojunction MWT solar module based upon 23%- effective cells

- Scientists in the Netherlands have actually asserted that a heterojunction steel wrap-through solar module they are designing could offer a 4% performance enhancement over traditional heterojunction panels.

The Netherlands Organisation for Applied Scientific Research (TNO) is partnering with tools supplier Eurotron, solar project developer GroenLeven, as well as Dutch research institute SIEC to create a new metal-wrap-through (MWT) solar module based upon heterojunction solar cell technology.

The brand-new "Whooper" panel has actually already demonstrated record efficiencies, according to its designers.

" Over 23% solar cell efficiency on six-inch silicon wafers has actually currently been demonstrated throughout the proof-of-principle phase with our commercial partner CIC," Gianluca Coletti, TNO's program supervisor for tandem PV modern technology and applications, informed pv magazine. "The principle has actually been further shown utilizing other partners' heterojunction pilot lines."

The research study team described that the Whooper module integrates silicon heterojunction solar cells with back-contact aluminum foil innovation into a module that is "prepared for mass production." They have likewise claimed that the back-contact aluminum foil innovation is the most effective and also stylish remedy for the interconnection of heterojunction solar cells.

"Because the majority of the calls are positioned on the back, the front of the module is visually far more enticing," they explained. Contrasted to conventional heterojunction panels, the new modules are claimed to give 4% even more power return at a 3% reduced levelized cost of power (LCOE).

TNO supervises of the design as well as optimization of the Whooper cell innovation, as well as currently recognized cell producers to show the expediency of producing on a commercial pilot line. The cell modern technology is based upon six-inch monocrystalline silicon wafers and also have actually been formerly utilized as bottom devices for the advancement of four terminal tandem silicon/perovskite cells and also modules.

Back-contact expert Eurotron will be responsible for creating a full-size module stack from backsheet to glass and also guaranteeing compatibility with its current industrial production line.

"The business will even more create the currently readily available stencil print technology, investigate the optimal circulation of the paste dots throughout the surface area, and also increase speed and also result of solar modules up to 90 solar modules per hour," Eurotron claimed.

It added that it will certainly also manufacturer test modules in Eurolab, its lab for the pre-production of back-contact solar modules as well as R&D jobs.

GroenLeven will release and check the Whooper photovoltaic panels at a field laboratory run by the SIEC study institute, which will utilize unique installing frameworks resembling those of rooftop PV systems.

"This supplies a secure and also regulated environment to do testing as well as they will certainly hold expertise circulation conferences on website," the researchers described.

They are making the module under a research study project supported by the Topsector Energy aid program of the Dutch Ministry of Economic Affairs and also Climate Policy, applied by the Netherlands Enterprise Agency (RVO).

Also read