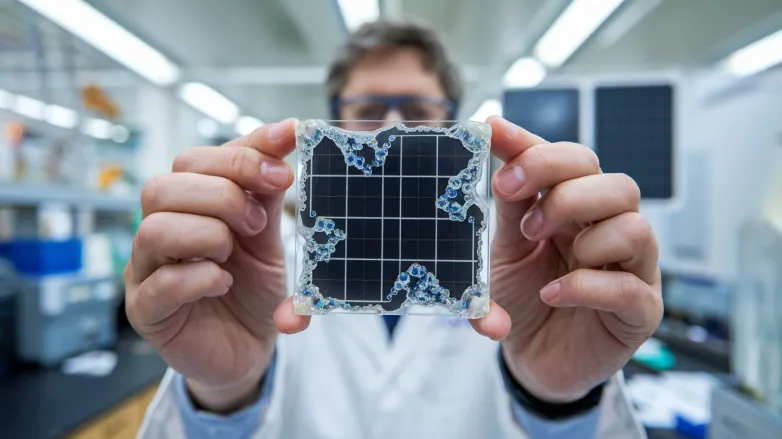

GCL Sets 29.51 % Record for Large Perovskite-Silicon Tandem Module Efficiency

- GCL’s 2,048 cm² perovskite-silicon tandem module hits 29.51 % NIM-certified efficiency, boosted by an AI-driven, high-throughput production line primed for GW-scale rollout.

Chinese solar innovator GCL Optoelectronics has pushed the performance bar once again, announcing that its 2,048 cm² perovskite-silicon tandem module has achieved a 29.51 % power-conversion efficiency, a figure certified by the National Institute of Metrology (NIM), China. The result eclipses the same module’s 27.34 % mark recorded a year ago, delivering an annual gain of more than two percentage points.

AI speeds lab-to-factory learning

The milestone rides on what GCL calls the world’s first AI-powered high-throughput perovskite manufacturing system. Equipped with 52 precision sensors, the line fabricates roughly 300 test cells daily while feeding 1,800 data points into a self-learning algorithm that tweaks deposition parameters in real time. According to the company, the closed feedback loop cuts lab-to-factory transfer times by up to 90 %—a critical edge in the sprint toward commercial tandem production.

Uniformity and scalability

Alongside record efficiency, GCL stresses batch-to-batch performance variation below 0.75 %, signalling that uniform coatings can be reproduced on large substrates—often the Achilles’ heel of perovskites. The company’s roadmap pairs “gigawatt-scale production with scenario-based demonstrations,” targeting mass manufacture of 2.76 m² tandem modules at a new China facility slated to start up by end-2025 with an expected annual output value of roughly CNY 1 billion (USD 139 million).

Wider technology push

GCL is also progressing pure-perovskite devices: in April it reported a 19.04 % efficiency on a 1 m × 2 m single-junction module, underlining a portfolio approach that spans both tandem and mono-perovskite formats.

Industry context

Efficiency gains north of 30 % are viewed as the next inflection point for mainstream solar, potentially slashing the levelised cost of electricity by allowing more watts per square metre of module and balance-of-system hardware. Rivals such as LONGi, Tongwei and Meyer Burger are all racing to crack stable, large-area tandems, but GCL’s NIM-verified result now sets the global large-module benchmark.

With certification in hand and AI-optimised tooling coming online, GCL argues it is positioned to ship gigawatt volumes of tandem panels from 2026 onward—a timeline that could accelerate the industry’s shift from single-junction PERC and HJT lines to perovskite-boosted architectures delivering efficiencies once limited to lab cells.

Also read