Fast Prototyping Boosts Solar Efficiency and Sustainability

I was sitting near my window the other morning, coffee cooling a little faster than I expected, watching the way the sunlight skated across the floor. Something about that quiet scene made me think about how quickly our energy habits keep shifting. We keep asking more from the sun, more from our devices, more from the companies building the gear that captures all that light. And honestly, it still surprises me how much of that progress depends on tiny boards nobody sees, the kind that get tested again and again before they ever make it into a real solar product.

That early stage makes or breaks the whole journey. Which is why many engineers lean on fast methods like WellPCB prototype assembly to move ideas along without getting stuck in long production cycles. It sits near the start of the process, but it shapes everything that follows.

So what does fast prototyping even look like?

You know what, it helps to picture a regular kitchen first. If you ever tried a new recipe, you probably tweaked it a few times. A little more salt here, a shorter simmer there. Scale that feeling up to solar hardware design. Except the stakes are higher, the materials are far more sensitive, and the pressure to move fast feels constant.

Quick PCB prototyping works a bit like those first test batches. Engineers assemble small runs to see how circuits behave under heat, shade, vibration, or sudden shifts in voltage. Nothing glamorous. Plenty of trial and error. But each round teaches something that flows into the next.

And here’s the thing. Solar tech depends on tight coordination between panels, sensors, tracking controls, small processors, and storage. If one tiny part misbehaves, the whole system drifts off rhythm. Prototyping smooths that rhythm before things get expensive.

Why solar teams rely on speed

Modern solar companies feel the pressure of shorter launch windows. Markets shift fast, climate goals keep tightening, and customers expect panels that work better, install faster, and last longer. A slow process can push a promising concept right out of relevance.

Fast prototyping helps for a few reasons:

-

It cuts down waiting time between design updates.

-

It lowers the cost of catching mistakes.

-

It reduces the risk tied to larger production runs.

-

It helps teams compare performance across materials or layouts.

Nothing groundbreaking here on its own. But when you add it up, you get cleaner design decisions that settle into reliable patterns.

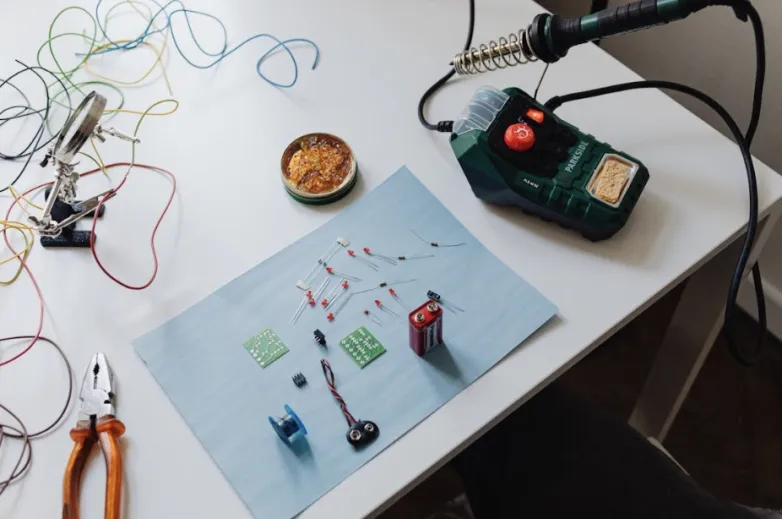

Sometimes these cycles happen in a cramped lab that feels like a warehouse mixed with a tech garage. Someone tests a board under bright lamps. Someone else tracks the resulting data on a screen that looks older than the system they are trying to improve. The scene feels messy, almost chaotic. Yet things keep moving because there is no other way to keep up.

Let me explain why tiny boards matter so much

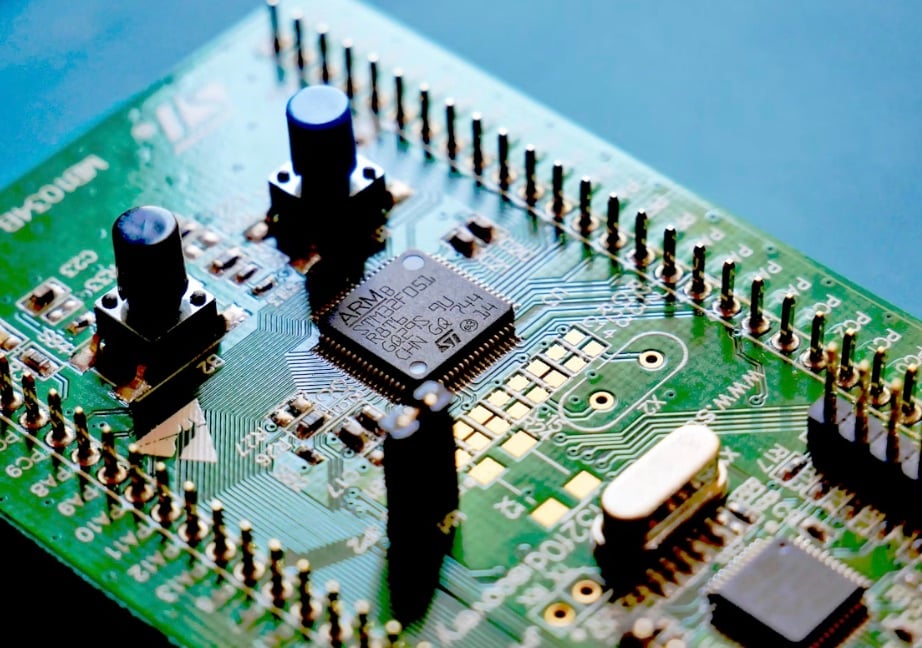

A single solar product often runs on several small circuit boards. One might handle power conversion, one might monitor temperature, and another might control communication between the unit and a cloud dashboard. If those boards lose even a small amount of efficiency, the whole system becomes less reliable.

Fast prototyping lets teams rearrange parts with minimal fuss. They can test new sensor modules, switch to higher performing regulators, or experiment with lighter materials. Sometimes they even bring back older methods because an unexpected detail ends up performing better in the field.

I know that sounds counterintuitive. You would think fresher parts always win. But real sunlight behaves differently than lab conditions. Dust, humidity, or small shadows can throw surprises at even the most refined system. That is why fast prototyping thrives. It adapts to real life.

The hidden sustainability factor

People talk about clean energy all the time, but you rarely hear how its success depends on responsible design methods. Prototyping gets a strange reputation as wasteful since you make small batches that might not end up in a final product. Yet when done carefully, it reduces waste in the long run.

Think about it this way. If a company builds thousands of units based on a weak design, those units might fail early. That becomes real waste. Prototyping lowers that risk. It teaches engineers what works before committing to materials, shipping, packaging, and installation.

There is also a habit among thoughtful teams to recycle parts from earlier prototypes. They reflow components, reuse connectors, and store usable boards for future comparisons. It might not make headlines, but it cuts the environmental footprint quietly.

A quick detour into real field challenges

I heard from an engineer once about a solar tracker that kept spinning out of sync with the sun. Nothing dramatic, but enough to cut efficiency. The culprit turned out to be a small circuit that struggled with temperature swings near desert sites. They caught it early because of a series of rapid prototypes that exposed subtle timing issues.

Stories like that echo across the industry. A prototype might survive controlled tests but falter under rain or dust or the odd way shadows move across rooftops in different regions. These moments force teams to adjust designs with a kind of humility. It reminds them that nature does not bend to schedules.

How fast cycles encourage creativity

Speed changes behavior. When teams know they can test something quickly, they take more creative risks. They try unusual layouts, stack components in strange configurations, or explore sensor combinations that might have seemed too quirky in a slower system.

Some of these experiments fail within minutes. Some turn into the next generation of solar controllers. The important part is the freedom to explore without getting bogged down. Prototyping gives a sense of play, which might sound odd in a technical setting, but it matters more than people think.

Engineers sometimes stay late for those playful sessions. The lab lights buzz a little. Someone hums without realizing it. Someone else scribbles notes on a piece of cardboard because the whiteboard markers are dry again. It feels human and imperfect, and those imperfect moments often lead to the best ideas.

Image source unsplash.com/photos/green-and-black-computer-motherboard-yQpAaMsQzYE

Why PCB layout influences energy efficiency

Not everyone realizes how much the arrangement of tiny copper traces affects energy flow. Even a slightly inefficient route can cause heat buildup or small drops in voltage. These issues drag down performance over time.

Fast prototyping gives room to test multiple layouts. You might see one board running cooler, another responding faster, and a third offering better longevity. Teams look at these differences like chefs checking the consistency of a sauce. Tiny shifts make the final dish feel right.

This process also encourages small tweaks that improve sustainability. If a board stays cooler, it lasts longer. If it lasts longer, it reduces long term waste and lowers the need for replacement parts.

The time to market advantage

If you have ever followed solar product launches, you know they come in waves. Manufacturers race toward seasonal peaks, often aiming for early summer or just before major climate conferences. A slow prototyping cycle can push a launch out of that crucial window.

Fast prototyping reduces the gap between an idea and a version that feels ready for customers. It helps teams lock down reliable designs without rushing through decisions. Customers get better products sooner, and companies stay competitive.

Sometimes this speed shakes loose unexpected opportunities. A design built for rooftops might suddenly look useful for small farming systems. Or a controller meant for large grids might scale down nicely to portable units. You get these surprises when the production rhythm stays agile.

A small note on cost efficiency

Solar companies have to balance performance with affordability. Prototyping sounds expensive, but it trims the budget over time. When a faulty board is caught early, the cost stays small. When it slips into full production, the cost balloons.

Fast prototyping acts like a financial pressure valve. It releases strain by catching problems early. Some teams even track cost per prototype against projected savings, almost like a quiet scoreboard that keeps everyone honest. It is not glamorous, but it works.

What the future might look like

If you follow industry trends, you can see how automation, smarter inspection tools, and new materials keep shaping the prototyping landscape. Some teams test boards with AI assisted optical checks. Others rely on small robotic arms for repeatable solder placements. But even with these tools, the heart of prototyping stays human.

Engineers still argue about layout choices. Someone still forgets to label a wire. Someone else still gets excited about a voltage graph that finally looks clean. The pace quickens, but the human element anchors the whole process.

As solar systems expand into neighborhoods, farms, factories, and community microgrids, the need for fast prototyping will only grow. It feels like a quiet backbone of innovation. Not flashy. Not widely discussed. But essential.

Closing thoughts

If you look back at that morning sunlight on the floor, it becomes easier to appreciate how much effort goes into capturing something so simple. Fast prototyping keeps that effort grounded. It keeps solar technology moving forward at a pace that reflects our changing habits.

Maybe that is why the field feels so personal. Every small improvement brings us a little closer to using sunlight in a way that feels natural and sustainable. And for a process built on endless testing, that sense of progress feels surprisingly warm.

Also read