Development of big area, organic solar cell printing technology

- Solar cell technology is a prominent clean energy resource. Particularly, organic solar cells, part of the third generation of solar cells, are getting attention as a core technology for metropolitan solar ray energy generation as they can be printed and related to exterior wall surfaces or glass windows of buildings.

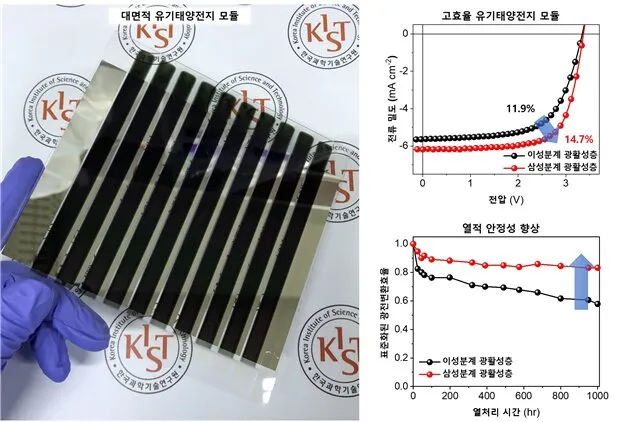

However, the photoactive area that soaks up sunlight and also converts it to electrical power stays dramatically smaller than 0.1 centimeters ². Furthermore, commercialization is blocked by performance as well as reproducibility problems that occur when increasing the cell area to a number of m2 where sensible energy supply degrees are available.

A study group led by Dr. Hae Jung Son of the Advanced Photovoltaics Research Center at the Korea Institute of Science and Technology (KIST; President: Seok-Jin Yoon) found the variables creating performance destruction in large-area organic solar cells and also revealed the development of a new polymer additive material for large-area, organic solar cell technology development.

The research study group focused on the photoactive layer's compositional form in organic solar cells and also the solution procedure, which is a part of the organic solar cell manufacturing procedure. The spin coating method, a solution procedure primarily utilized in the laboratory research study stage, creates a consistent photoactive layer blend as the solvent vaporizes swiftly while the substratum turns at a broadband. Nonetheless, the large-area, continuous service procedure made for commercial use created solar cell performance degeneration because the solar cell product option's solvent dissipation rate was as well slow. Consequently, undesirable aggregation in between the photoactive materials can be formed.

The study team developed a polymer additive that can stop this sensation by interacting with products prone to aggregate. Therefore, ternary photoactive layers including polymer additives were fabricated to avoid aggregation in photoactive layers. Furthermore, owing to possible nano-level structure control, solar cell performance improvements and stability safety are gotten against light-induced temperature boosts throughout solar cell operation. A 14.7% component efficiency was attained, leading to a 23.5% performance boost contrasted to that of the traditional double star. Efficiency and also security were simultaneously demonstrated by keeping over 84% preliminary efficiency for 1,000 hrs, even in an 85 ℃ warmed environment.

KIST's Dr. Son specified that they "have actually gotten closer to organic solar cell commercialization by suggesting the core principle of a solar cell material efficient in top quality, large-area solution processing," further revealing that "commercialization via follow-up research will make eco-friendly self-sufficient energy generation possible that is quickly relevant to exterior building wall surfaces as well as automobiles as well as also used as an energy resource for mobile as well as IoT devices."

The research study was published in Nano Energy.

Also read