Determining early-stage staining in EVA encapsulants

- A brand-new, non-destructive approach has actually been suggested by scientists in India that state recognizing early-stage staining in EVA encapsulants can aid discover deterioration in photovoltaic panels prior to power outcome is impacted. The researchers utilized an ultraviolet increased maturing examination throughout 34 days on 3 encapsulant examples.

Recognizing early-stage staining in the ethylene-vinyl acetate (EVA) copolymer encapsulants made use of for crystalline solar module lamination can detect panel deterioration prior to power result is impacted.

Staining decreases straight short circuit existing, making it a prime resource of minimized panel efficiency, together with early delamination.

Scientists led by academics from the Indian Institute of Technology (IIT) Bombay have actually recommended a brand-new, non-destructive technique of finding early-stage photobleaching as well as staining in EVA encapsulants. Both sensations were referred to as 'contrary response devices' in encapsulants by the scientists.

Staining, triggered by the visibility of conjugated substances, volatiles and also various other aeriform components, results in the look of fluorophores-- fluorescent chemical substances which obstruct UV light and also decrease light passage and also reflectance within PV panels. When fluorophores are transformed to non-fluorescent type and also is normally local at the sides of solar cells as well as does not obstruct efficiency, photobleaching happens.

Non-destructive

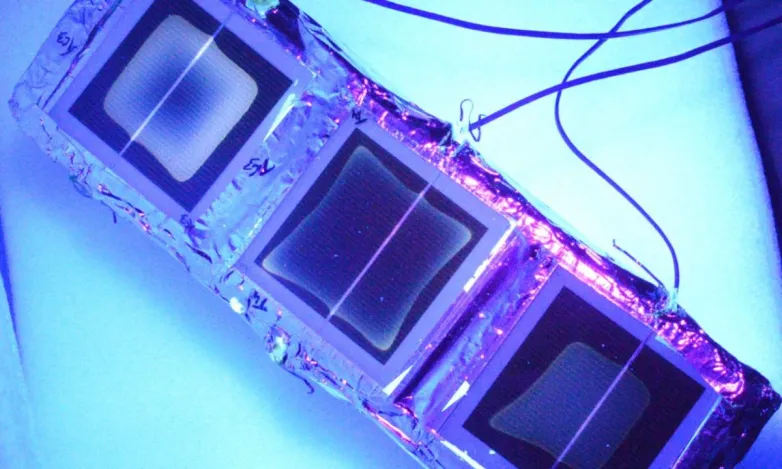

To find early-stage staining and also photobleaching, the IIT Bombay team utilized fluorescence imaging, which is normally utilized to find EVA encapsulant deterioration, and also Raman spectroscopy, a method made use of to observe vibrational, various other and also rotational states in molecular systems. The scientists evaluated UV-cut (C), UV-transparent (T) as well as integrated-- TC-- EVA encapsulant, single-cell solar module examples in a UV accelerated-aging examination. The examples were put over 12cm thick glass woollen insulation and also securely loaded with light weight aluminum tape.

The outcomes revealed the order in which both contrary response systems took place varied relying on the nature of the cell which undertook the sped up aging procedure.

" It is discovered that the oxygen diffusion coefficient of the T example is 4 as well as 9 times slower than the TC as well as C examples, specifically, in the photobleached area," the researchers stated. "Fluorescence imaging as well as ranges as well as Raman ranges were taken previously and also after the increased examination and also suggested that staining triggering fluorophore generation was greater after [photobleaching] for consolidated as well as clear EVAs, whereas [it was] greater at the facility for UV‐cut EVA laminates."

Various staining

After the aging examination, the scientists evaluated the distinction in between the 3 examples with ultraviolet-visible spectroscopy and also a colorimeter.

The IIT Bombay team claimed, after 34 days of UV accelerated-aging, their unique method worked at recognizing early-stage photobleaching as well as staining.

" The major searching for of this research study is that staining initiation is various for the c-eva and also the t-eva examples," they wrote in the paper Early‐stage recognition of encapsulants photobleaching as well as staining in crystalline silicon photovoltaic module laminates, released in Progess in Photovoltaics.

According to the searchings for, staining of the encapsulants started after photobleaching beside cells as well as relocated in the direction of the main area of the T and also TC examples. Nonetheless, in the C example, staining began with the main area as well as transferred to the edges. "Fluorescence and also Raman ranges revealed that there [were] no unsaturated fluorophores existing in the photobleached area, whereas the staining area [revealed] solid unsaturated fluorophore fluorescence," the paper kept in mind.

" This job develops a considerable effect in the location of PV module encapsulation as well as might lead to the market taking on the strategies to determine the preliminary phases of staining in various encapsulants prior to producing ... PV components," the IIT Bombay team specified. "It will certainly likewise aid the sector in picking the appropriate encapsulant product for the procedure of PV components in various weather problems."

Also read