Design of a nanometric structure that enhances solar cell efficiency

- Researchers at the Universidad Carlos III de Madrid (UC3M) have established a brand-new nanometric framework that can cover the surface area of some silicon photovoltaic panels and enhance their efficiency by approximately 40%. This design could be put on future solar installments to achieve a better power performance.

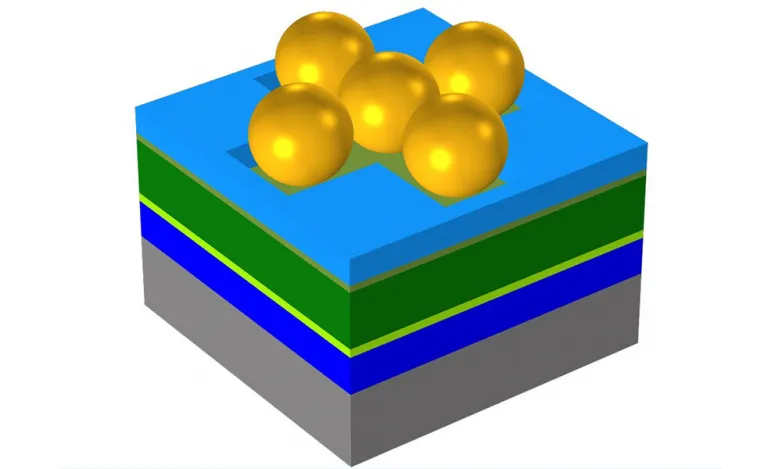

This brand-new design is based upon a "metasurface," to put it simply, a surface composed of tiny structures that are repeated in a pattern. Along with this, both the structures as well as the pattern are smaller sized than the wavelength of light. This indicates that they need to be nanometric in dimension (millionths of a millimetre), clarify scientists from the UC3M's Displays and Photonic Applications Group (GDAF, in its Spanish phrase). This is a surface area comprised of small structures that are duplicated in a pattern. Along with this, both the structures as well as the pattern are smaller sized than the wavelength of light.

The design they have recommended is to emboss crosses on a hydrogenated amorphous thin-layer silicon solar cell, especially, on the clear conductive layer where the light gets in. After that, dielectric product nanospheres fill these crosses. By doing so, the light that reaches the cell is effectively redirected to its active area, the place where it is changed right into an electric current by the photoelectric impact. Using this method, even more light can be caught in the solar cell, generating approximately 40% more of generated current, according to their estimations, which have been published in a paper in the Solar Energy journal.

In this work, researchers have had the ability to determine the proper material for the nanospheres, such as zinc oxide, as well as the appropriate dimension so that it's feasible to make them currently: a distance of 210 nanometres (the thickness of a human hair arrays from 60,000 to 80,000 nanometres).

" The trick to achieving this properly in specific "colours" is choosing the right sizes and materials," describes among the study's authors, Ricardo Vergaz, lecturer at the UC3M's Department of Electronic Innovation. "We have reviewed countless feasible sizes and also refractive indices, one of the most vital optical property of the rounds' product," he adds.

The approach: incorporate diffraction and resonant effects

Embedding the rounds right into the crosses, and for that reason, bringing them somewhat more detailed to the energetic layer below, raises their effect significantly, the researchers highlight in the research. Along with this, they have located that the mix of the effect of the crosses and rounds is what causes this improvement. If the crosses are separated, or the rounds are lowered, the impact declines dramatically.

"We have actually tried to enhance the diffraction created by the crosses by the powerful impacts of the rounds themselves," notes another of the research study's writers, Braulio García-Camara, a researcher at the GDAF. "The contrasts in between the refraction indices of the nanospheres and also those on the lower layers permit us to exploit the effects we were looking for. When this style can be applied right into manufacturing, a significant enhancement in performance will be achieved in solar cells mounted in future solar areas," he wraps up.

Another advantage of this style is that the results created allow the thickness of the energetic layer to be reduced in order to create the current effectively, saving product throughout the manufacturing procedure. "By reducing this, the removal of electrons produced by light is also extra efficient, as they have less course to cross where they could be reabsorbed," they highlight. Along with this, the absorption that takes place in the layers surrounding the energetic layer has a warming result, which can allow its flaws to be reduced in the long term.

Also read