Collecting solar energy from both sides: New process boosts performance of bifacial CIGS thin film solar cell

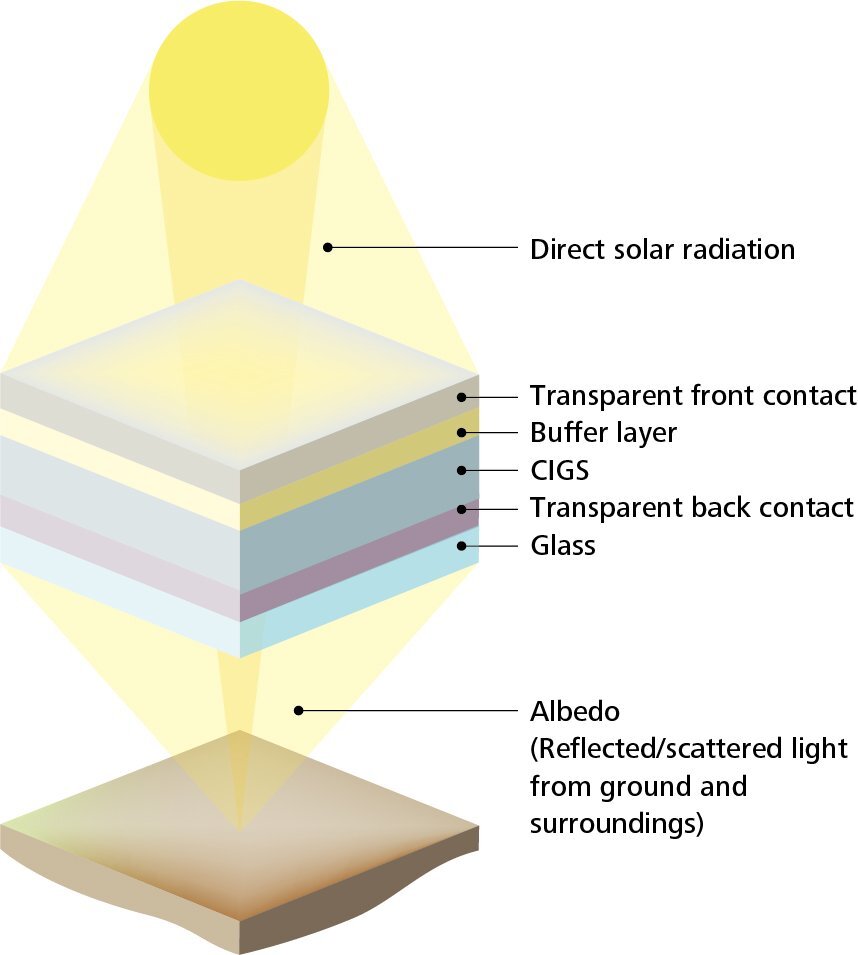

- The suggestion is as uncomplicated as it is basic: If I can collect both direct sunlight along with its reflection through the rear end of my solar cell, this need to enhance the yield of energy the cell creates.

Potential applications are, for instance, building-integrated photovoltaics, agrivoltaics-- the synchronised use locations of land for both photovoltaic power generation and farming-- and also up and down or high-tilt installed solar modules on high-altitude premises.

Get in the bifacial solar cell. According to the International Technology Roadmap of Photovoltaics, bifacial solar cells could catch a market share of 70% of the overall photovoltaics market by 2030.

Although bifacial solar cells based on silicon wafers are currently on the marketplace, thin film solar cells have up until now dragged. This is, a minimum of in part, as a result of the instead reduced effectiveness of bifacial CIGS thin film solar cells triggered by a vital traffic jam trouble: For any type of bifacial solar cell to be able to collect reflected sunlight at the rear side, an optically transparent electrical get in touch with is a prerequisite. This is accomplished by using a transparent conductive oxide (TCO) that replaces the nontransparent back contact in conventional-- i.e. mono-facial-- solar cells made of molybdenum.

A detrimental oxide formation

And that's where the issues begin. High-efficiency CIGS solar cells are normally generated by a high-temperature deposition procedure, i.e., above 550 degrees. At these temperature levels, nevertheless, a chain reaction happens in between the gallium (of the CIGS layer) and also the oxygen of the transparent back contact-- an oxide. The resulting gallium oxide interface layer blocks the flow of sunlight-generated existing and also hence reduces the energy conversion performance of the cell. The highest values achieved thus far in a solitary cell are 9.0% for the front side as well as 7.1% for the rear side.

" It's really difficult to have a good energy conversion performance for solar cells with both front as well as rear transparent carrying out contacts," states Ayodhya N. Tiwari, who leads Empa's Thin Film and Photovoltaics lab.

So, Ph.D. student Shih-Chi Yang in the group of Romain Carron in Tiwari's lab developed a new low-temperature deposition process that ought to create much less of the detrimental gallium oxide-- preferably none at all. They made use of a small amount of silver as a secret component of types to lower the melting point of the CIGS alloy and to obtain absorber layers with good electronic properties at just 350 levels deposition temperature level.

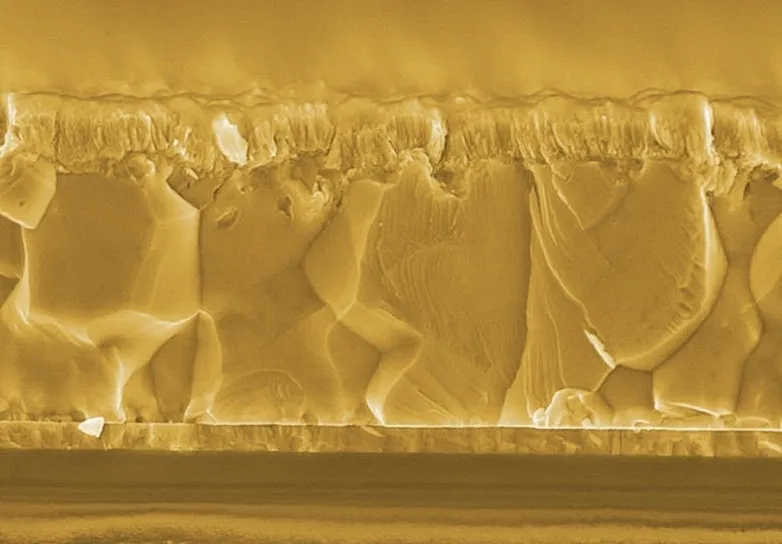

And also certainly, when they analyzed the multilayer framework with high-resolution transmission electron microscopy, with the help of Tiwari's previous postdoc Tzu-Ying Lin, currently at National Tsing Hua University in Taiwan, the group can not detect any type of gallium oxide at the user interface in any way.

The ambitious goal: An energy yield of greater than 33%.

This was likewise mirrored by a drastically improved energy conversion efficiency. The cell generated values of 19.8% for front illumination and 10.9% for rear illumination that had been individually licensed by the Fraunhofer Institute for Solar Energy Systems (ISE) in Freiburg/Germany-- in the identical cell on a glass substratum. What's even more, the team also prospered in making, for the extremely first time, a bifacial CIGS solar cell on a flexible polymer substrate, which-- because of their lightweight as well as flexibility-- broadens the range of prospective applications. And also ultimately, the researchers combined 2 solar technologies-- CIGS and also perovskite solar cells-- to create a bifacial "tandem" cell.

According to Tiwari, bifacial CIGS technology has the potential to produce energy conversion effectiveness beyond 33%, hence opening up better possibilities for thin film solar cells in the future. Tiwari is right currently attempting to develop a collective initiative with crucial labs as well as companies throughout Europe to quicken the technology advancement and its industrial manufacturability on a larger scale.

The findings are published in the journal Nature Energy.

Also read