Brand-new tools for solar cell metallization

- The system can metallize the front and also back sides of silicon solar cells with unprecedented accuracy and also rate, Fraunhofer ISE stated. The technology is likewise appropriate for elements such as printed motherboard or chip cards.

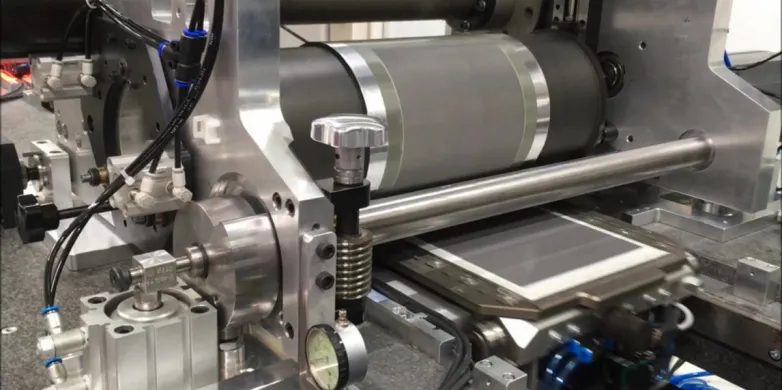

Germany's Fraunhofer ISE has actually evaluated and created turning processes for the production of silicon solar cells. The supposed "Rock Star" study project has actually currently been finished with the building of new demonstrator devices for solar cell metallization.

The equipment has the ability to transport the cells to be covered through self-governing "shuttle bus," with broadband and accuracy given by Swiss engineering group Gallus Ferd Rüesch AG.

Depending on the requirements, a rotating display printing unit and a flexographic printing device can be activated. Added printing and finishing processes-- such as multi-nozzle dispensing and intaglio-- can likewise be integrated, thanks to the devices's modular design, Fraunhofer ISE claimed.

The transportation system has the ability to convey the cells at a rate of approximately 600 millimeters per 2nd as well as can publish them with high accuracy, according to the research institute. If this is compared to the state-of-the-art metallization of solar cells, it represents an academic increase in throughput of 100% per track.

" The newly created technology therefore precisely fulfills the demands of sector for innovative technologies to significantly raise efficiency," described Florian Clement, head of manufacturing innovation in the structuring as well as metallization department at Fraunhofer ISE.

The project shows that it is feasible to effectively apply the front and also back metallization of highly effective PERC solar cells utilizing rotating display printing as well as flexographic printing, the institute stated.

" PERC solar cells with rotary screen printing metallization accomplished comparable quality and also electrical performance compared to reference cells metallized conventionally in flatbed display printing, yet enable substantial price savings due to the significantly increased throughputs," said Andreas Lorenz, a scientist at Fraunhofer ISE. "We were likewise able to generate the first operating demonstrator modules from solar cells with rotary printing metallization with SmartWire cord link. We therefore see excellent possibility of this modern technology for a wide array of applications, from solar cells to high-throughput covering of useful frameworks for sensors, smart cards or gas cells."

The "Rock Star" project was moneyed by the German Federal Ministry of Education and also Research (BMBF) as part of its "R&D for photovoltaics" funding program. Gallus Ferd Rüesch AG, at the same time, participated in the project by making use of its experience as a supplier of high-precision rotary printing systems and also industrially made display printing plates.

ContiTech Elastomer Coatings GmbH created micrometer-precise, laser-engraved printing plates. The project was clinically and also technically sustained by Fraunhofer ISE and the Institute for Printing Processes as well as Printing Machines (IDD) at the Technical University of Darmstadt. The connected companions in the project were Hanwha Q Cells GmbH and Kurt Zecher GmbH.

Also read