Big innovation for 'massless' energy storage

- Researchers from Chalmers University of Technology have actually created a structural battery that carries out ten times better than all previous variations. It includes carbon fiber that offers at the same time as an electrode, conductor, and also load-bearing product. Their most recent research study innovation leads the way for basically 'massless' energy storage in lorries and also various other technology.

The batteries in today's electric cars make up a large part of the automobiles' weight, without satisfying any kind of load-bearing feature. An architectural battery, on the other hand, is one that functions as both a power source and also as part of the structure - as an example, in an auto body. This is called 'massless' power storage, because essentially the battery's weight vanishes when it becomes part of the load-bearing framework. Computations show that this type of multifunctional battery might significantly decrease the weight of an electrical vehicle.

The growth of architectural batteries at Chalmers University of Technology has proceeded through several years of research study, consisting of previous discoveries including specific types of carbon fibre. Along with being tight as well as strong, they also have a good capability to save electric energy chemically. This work was named by Physics World as one of 2018's ten largest clinical breakthroughs.

The initial effort to make an architectural battery was made as early as 2007, yet it has actually until now proven difficult to manufacture batteries with both great electric as well as mechanical homes. Now the advancement has taken an actual progression, with researchers from Chalmers, in partnership with KTH Royal Institute of Technology in Stockholm, offering an architectural battery with properties that much surpass anything yet seen, in terms of electric energy storage space, rigidity and also strength. Its multifunctional efficiency is 10 times greater than previous architectural battery models.

The battery has a power density of 24 Wh/kg, indicating roughly 20 percent ability contrasted to similar lithium-ion batteries presently available. But given that the weight of the lorries can be considerably reduced, much less power will be needed to drive an electric vehicle, as an example, and lower power density additionally leads to boosted safety. And also with a stiffness of 25 GPa, the structural battery can really take on numerous various other generally made use of building and construction products.

" Previous attempts to make structural batteries have actually caused cells with either good mechanical homes, or good electric properties. However here, making use of carbon fibre, we have actually done well in making an architectural battery with both affordable energy storage capability and also rigidness," explains Leif Asp, Teacher at Chalmers as well as leader of the project.

Super light electric bikes as well as consumer electronic devices could soon be a truth

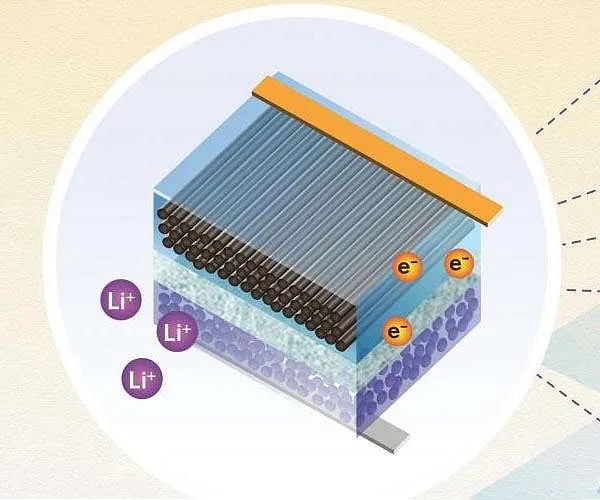

The new battery has an adverse electrode made of carbon fibre, and also a favorable electrode constructed from a lithium iron phosphate-coated aluminium foil. They are divided by a fibreglass material, in an electrolyte matrix. In spite of their success in producing a structural battery 10 times better than all previous ones, the researchers did not choose the products to try as well as break records - instead, they intended to check out as well as comprehend the effects of product design and separator thickness.

Currently, a new project, financed by the Swedish National Space Agency, is underway, where the performance of the structural battery will certainly be boosted yet further. The aluminium aluminum foil will be replaced with carbon fiber as a load-bearing material in the favorable electrode, supplying both raised rigidity and also power thickness. The fibreglass separator will certainly be changed with an ultra-thin version, which will certainly offer a much higher impact - in addition to faster charging cycles. The new project is anticipated to be completed within two years.

Leif Asp, that is leading this project as well, estimates that such a battery could reach an energy thickness of 75 Wh/kg as well as a rigidity of 75 GPa. This would make the battery about as strong as aluminium, but with a comparatively much lower weight.

"The future generation structural battery has amazing capacity. If you take a look at consumer technology, maybe rather feasible within a couple of years to make smart devices, laptop computers or electrical bikes that evaluate fifty percent as high as today and also are far more portable", states Leif Asp.

And in the longer term, it is absolutely conceivable that electric autos, electric airplanes and also satellites will certainly be made with as well as powered by structural batteries.

"We are actually only restricted by our creative imaginations below. We have obtained a lot of focus from many different types of firms about the publication of our scientific posts in the field. There is naturally a fantastic amount of passion in these lightweight, multifunctional products," claims Leif Asp.

Also read