Bifacial modules: The difficulties as well as advantages

- Bifacial modules are among the older advancements in photovoltaic panel technology, going back to the 1960s. It is also among the current developments to take hold. According to many professionals, nevertheless, it is now on the right track as the current trend to sweep the solar industry as well as will quickly become the criterion.

Bifacial modules have actually been around since the 1960's, yet it has been the advancement of PERC (passivated emitter rear cell) innovation that has actually dramatically increased their performances and produced the potential for them to be a turbulent gamer in the solar PV market.

That claimed, there are lots of variables which should be resolved before bifacial modules can assert a significant market share. Cost is among the largest elements a big aspect --- particularly in the case of monofacial modules.

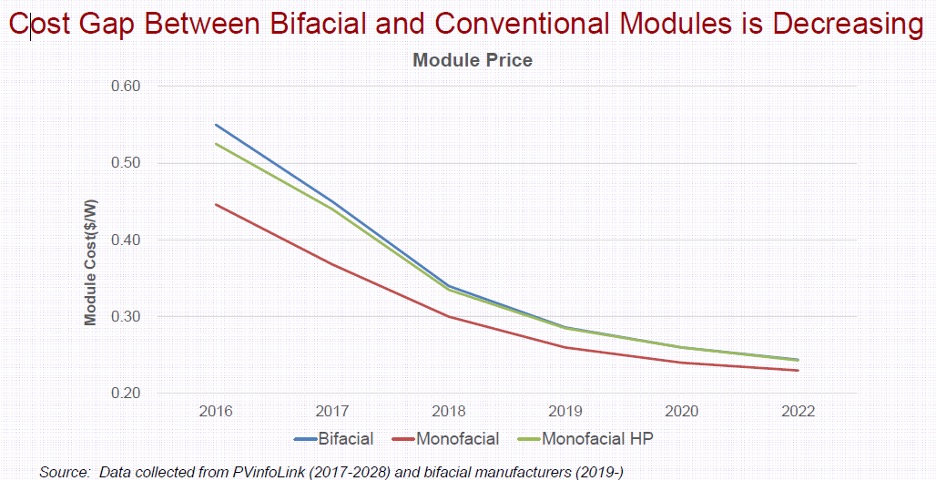

Like for standard solar modules, the price of bifacial modules has dropped precipitously over the last twenty years. Especially, as costs have decreased, so also has the expense gap in between mono- and bifacial modules.

The graph over programs among the primary reasons bifacial module market share is forecasted to continue to raise. As the price gap lessens, as well as bifacial manufacturing rises (indicating more readily available data and also improved design), the extra production prices resulting from producing the back side of bifacial modules can make up for extra costs.

But is raised production sufficient to cover the extra prices? The response is: it's complicated. While the raised price of tools and setup prices of bifacial PV plants are not excessive, there are other variables preventing widespread fostering.

For example, there are many design elements one-of-a-kind to bifacial systems that contribute to greater general installment expenses; in particular, the back side of the modules. The DC style, site location, and setup can be much more testing for a bifacial plant versus one with monofacial modules, and also this can produce problems for capitalists. It is likewise quite challenging to accurately predict the enhanced result for a system layout, because of the many variables that affect back side manufacturing.

Exact dimensions

There is no question bifacial modules will raise power manufacturing. The question is how to precisely gauge the cost of the bifacial plant, and exactly how to properly predict the power production with every one of the variables represented.

Outcomes and research studies have actually revealed that bifacial modules can produce extra power between 10-20% over monofacial panels. If conditions are maximized and solitary axis trackers adopted, the additional power can be as high as 30-40%.

It is essential to keep in mind that we are searching for the optimal LCOE (levelized cost of electricity), not the maximum power feasible. There are numerous ways to boost power production, but many of these options are not cost effective and also, for that reason, not useful on the market. As an example, dual axis tracking can increase power production, but it is still too pricey to be advised. So a major obstacle for bifacial modules in the marketplace is the problem in producing precise simulations and also consequently satisfying financial questions regarding the additional costs.

Enhanced testing as well as boosted modeling have been underway for many years, and also improvements in offered information pertaining to irradiance, as well as geospatial information have added significantly to renovations in these simulations. There have actually additionally been lots of bifacial test sites constructed, bifacial researches undertaken, and bifacial installations finished supplying actual data. Actually, despite all the obstacles and uncertainties, bifacial installments have proliferated in the last fifty percent years, from only 97MW of mounted worldwide capability in 2016, to virtually 6 GW in 2019.

The biggest bifacial plant to day-- 224 MW-- was completed in late 2019. That growth is forecasted to continue. According to Wood Mackenzie Consultancy, bifacial modules will certainly account for 17% of the global market for photovoltaic panels in 2024.

With every one of the information from tests and completed setups, we do have a design of just how to make bifacial panels benefit a reduced LCOE.

A few of the very best practice suggestions to enhance your bifacial installation and attain increased ROI as well as reduced LCOE are as complies with:

- Site option: The cost of land affects how bifacial can be enhanced. For places where land is limited as well as pricey, panels should be laid level on the ground to guarantee optimum energy collection over a given land area. Nevertheless, where land is cheap, bifacial modules can have optimum spacing as well as a result greater yields. Additionally, bifacial yields are greater where the diffuse light power is better, which means at higher latitudes the bifacial return will be above at lower latitudes.

- High albedo: The atmosphere chosen need to have a high albedo. Desert sand is a good option. The best alternative is white concrete or very reflective roofing aluminum foil. Snow and also ice also has extremely high albedo.

- Panel height: This will certainly vary from site to website, but 1 meter has offered excellent advantage to set you back ratios. Enhancing panel height calls for other variables to be measured too, such as wind speed and lift from the tilt and therefore requires stronger ground mounts.

- Tilt: This will certainly differ from website to website, yet normally 2 ~ 15 degrees more than the monofacial tilt has actually been shown to be effective.

- Row distance: Again, this will certainly vary from website to website, however 6 to 8 meters row distance has actually been revealed to create great outcomes. Of course, the cost of land or the offered area need to be thought about, as well as if the cost of land is too great, then a higher row distance will increase your LCOE. Ideally, somewhere that land is really affordable can be utilized to raise row distance expense efficiently.

- Greater MPPT density: Using string inverters with even more MPPTs (maximum power factor tracking) is an effective method to minimize string mismatch and ensure reliable efficiency. The even more MPPTs per watt the far better.

- Solitary axis tracker: Researchers from the Solar Energy Research Institute of Singapore have wrapped up that bifacial installations with solitary axis tracking can boost power return by 35% as well as get to the lowest LCOE for a lot of the land area on earth. Although dual-axis trackers attain the highest power generation, their expenses are still expensive as well as are as a result not as budget-friendly. The scientists wrote: "In basic, with the same mounting structure, bifacial arrangement outperforms monofacial setup. Tracker configurations outmatch fixed-tilt configurations dramatically, with dual-axis tracker installments having marginally greater return than one axis."

Price analyses have shown that the cost of tools and also installment of a bifacial PV plant will be around 5% more than a similar monofacial plant. Furthermore, the information reveals that the price of adding a solitary axis tracking system for optimal returns includes one more 10% to the equipment and setup costs over an equal setup with no tracking.

For that reason, a bifacial, single axis tracking (1T) pv plant can set you back roughly 15% more than an equivalent monofacial non tracking PV plant.

The yields from a bifacial 1T plant can be well over 20%, approximately 35 to 39% sometimes if conditions can be maximized.

After working with lots of computations and evaluating several production models and also spread sheets, right here is a table of recommendation worths and also instances to help comprehend several of the variables:

| Bifacial PV plant examples | ||

| No tracker, near equator, moderate albedo | Single axis tracker, high albedo, high latitude | |

| Albedo | 25% grass | 40-60% (achieved with desert sand white paint, or reflective roof ) |

| Rear side mismatch loss factor | 3% (achieved with high MPPT density | 3% (achieved with high MPPT density |

| Panel height | 1m | 1m |

| Single axis tracker | No | Yes |

| Row distance | 6m | 6m |

| Cost of land | Low | Low |

| Solar diffusion factor | Low (closer to equator) | High (achieved at higher latitudes) |

| Bifacial gain | 12-15% | 30-35% |

| Additional cost | 5-7% | 15-17% |

This sounds like a straightforward computation, yet we have another barrier to review, which is the sight from the money side of the equation.

Due to the unpredictability in modeling the costs as well as production of bifacial PV plants, and the reasonably tiny sample dimension of reputable efficiency data, financiers are often unwilling to fund the full amount of anticipated back side manufacturing. As a result, financiers might only value a portion of the designed bifacial gain.

As an example, if a job had actually predicted a gain of 10% over an equal monofacial project, a loan provider could be anticipated to supply 10% more financial obligation funding than for the monofacial project. Nonetheless, that lending institution may not value the complete projected bifacial gain, due to the unpredictabilities we have gone over. They may only value the predicted bifacial gains at 50%, indicating they would only use 5% even more financial obligation financing over the monofacial task.

And because debt financing is typically the least expensive form of financing, the uncertainties in the modeling and simulation stage wind up adding funding costs to the job, thereby enhancing the LCOE.

Final thought

In recap, the market is currently still battling to manage the variables of anticipating the result of bifacial modules, and also to manage the costs of enhancing the power produced by bifacial modules. These challenges are being slowly gotten over, nevertheless, with each development in information as well as innovation.

Concerning the writer

Nick Lusson has 10 years' experience in the solar industry in East Africa based in Nairobi. He is an author, motivational audio speaker as well as business consultant, presently working as Business Development Executive for Jubaili Bros Solar.

Also read