Batteries that can be assembled in ambient air

- The honor of the 2020 Nobel Prize in Chemistry mosted likely to those who developed lithium-ion rechargeable batteries. These batteries have actually become a vital energy source for electronic gadgets varying from tiny IT devices to electric vehicles.

Tesla, a leading U.S. automaker, just recently emphasized the requirement to establish an ingenious production system and minimize battery cost. The cost of batteries make up a huge part of electric lorries and cost decrease is important to promoting them.

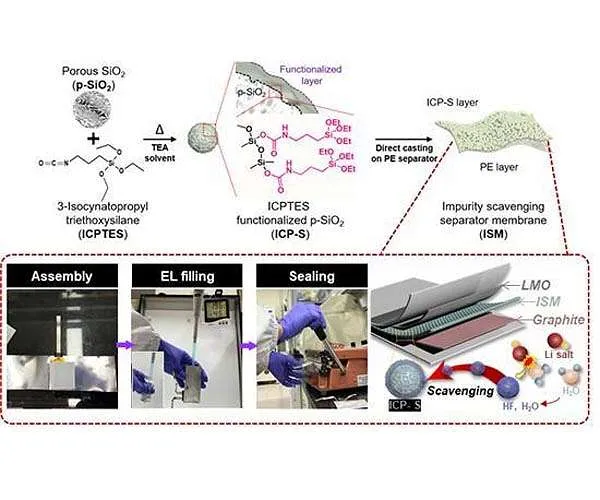

A joint study team, led by Professor Soojin Park and also Ph.D. prospect Hye Bin Son of POSTECH's Department of Chemistry with Professor Seungmin Yoo of Ulsan College, has successfully created a multi-functional separator which allows the batteries to work also when the bag cell is assembled in ambient air. These searchings for were introduced in the latest online edition of Energy Storage Materials.

Considering that the electrolyte inside the battery reacts with dampness to cause degeneration, lithium-ion batteries are typically set up in a dry room which maintains less than 1% moisture levels. Nevertheless, preserving a dry room is rather costly.

To address this issue, researches have been carried out to reduce impurities - such as wetness or hydrofluoric acid - by injecting ingredients right into the electrolytes. However these can create unwanted side responses throughout the battery procedure.

In fact, when batteries are activated at a heat (50? or higher), also a small bit of moisture creates faster performance damage. As a result, there is a demand for a material efficient in capturing moisture and also contaminations in the battery without unfavorable electrochemical responses to the additives.

To this, the joint research team introduced functional products that can catch pollutants externally of the separator to raise thermal security as well as enhance battery efficiency.

This multi-functional separator demonstrated superb warmth resistance (shrinkage within 10% after 30 minutes of storage space at 140?. Conventional separator had 50% shrinkage) and further showed improved electrochemical efficiency at the heat of 55C (79% of the initial capacity preserved after 100 billing cycles).

Furthermore, the researchers verified the effectiveness of the practical material in the electrolyte in the impurity-filled atmosphere. The silane compound externally of the synthesized useful ceramic traps dampness and also preserves the ceramic structure well, yet the basic ceramic product was worn away by the acidified electrolyte.

Additionally, via this study, the group verified that this multi-functional separator generated in the ambient air this time exhibits exceptional life-span than the standard separators, confirming that it gives steady performance beyond the role of a simple separator.

" This newly established multi-functional separator reveals wonderful security and outstanding electrochemical performance at high power thickness," said Professor Soojin Park who has long been studying battery separators with different strategies.

" With this initial effective case of producing batteries in ambient air, it is expected to play a large duty in decreasing battery price."

Also read