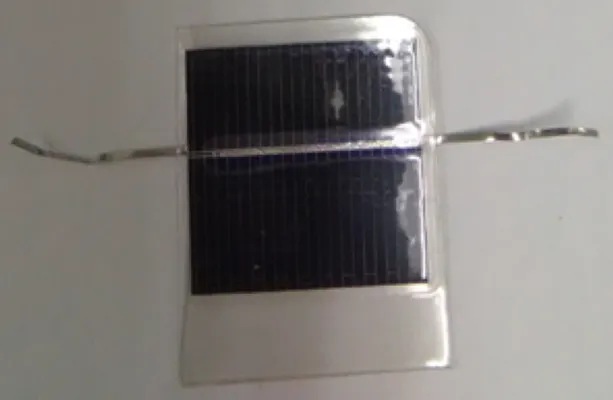

Bag lamination method for solar cell encapsulation

- Scientists in India have made use of a pouch laminator to encapsulate a polycrystalline solar cell. The resulting tool, the researchers claim, revealed much better UV photon absorption than solar cells treated with a polymer surface layer.

Scientists from the Madurai Kamaraj University in India have declared bag lamination-- of the type regularly utilized to strengthen papers by sealing them in a sturdy plastic covering-- could be made use of to envelop solar batteries.

The scientists state a solar cell they laminated flooring in such style provided far better ultraviolet (UV) photon absorption than devices treated with a polymer surface layer.

The research disregarded elements such as durability and also cost, to focus specifically on the technological practicality of releasing such a fast, low-cost encapsulant technique for screening at research laboratory degree. "The best benefit of this strategy would be its simpleness contrasted to standard lamination, which is tedious as well as energy consuming," research co-author Vasu Veerapandy told pv publication. "It can be executed making use of a tabletop pouch lamination maker which any type of research laboratory can manage."

Approach

The researchers enveloped a 3cm2 distinctive polycrystalline square solar PV wafer utilizing a pouch laminator as well as compared its performance with that said of a tool coated with polymethyl methacrylate (PMMA).

" The cell's diffuse reflectance with the encapsulant exhibits much better photon absorption in the UV region, which is confirmed from boosted external quantum performance," the researchers composed.

The group claimed, the encapsulated cell shed a tiny percentage of noticeable photons but electrical efficiency was not impacted. "On the other hand, the PMMA-coated cells showed a superior photon-to-electron conversion but [that] did not lead to reliable charge collection," the academics stated.

" We concluded that encapsulation via tiny range bag lamination would certainly be a much better passive approach [for] laboratory range speculative simulation of component performance [making use of] a cell, than a polymer surface finishing, which influences electrical homes of the solar batteries," claimed Veerapandy.

Cost

The research study co-author claimed the sort of lamination required can be attained for the cost of laminating flooring an identification card. "So it will not add any type of popular price to the tool fabrication," the academic stated. "The percent of damage is minimal if the tabbing [is] kept level, without crumples."

The researchers suggested the lamination approach could decrease the expense of using solar energy to power small scale study work with microbial decontamination, bioinstrumentation and using photometric systems for enzymatic nitrate metrology as well as water top quality, or for solar-powered waste recycling.

" The results of this research are promising and also indicate a need for future job," said Veerapandy. "The technique made use of in this research ought to be used on various other PV products to make sure that the results can be generalized and also are not only legitimate for crystalline silicon."

The research study co-author said the lamination strategy could be further compared with polymers made use of for front, back and sandwich finishings as well as the technique could be evaluated for resilience and under UV-accelerated problems.

The pouch lamination method was presented in the paper Demo of an easy encapsulation method for prototype silicon solar cells, as well as published on the ScienceDirect site.

Also read