Argonne materials scientists go after a new generation of batteries

- Progress in used research at Argonne National Laboratory increases hopes that solid-state batteries will certainly change standard lithium-ion batteries quicker rather than later.

Reenergizing the batteries in digital devices - as large as electric vehicles or as little as cell phones - has actually come to be as daily an activity as packing the dishwashing machine. The lithium-ion batteries that mostly power these tools are lightweight as well as affordable to produce. Nevertheless, they are by nature inflammable, which raises problems concerning their security and dependability as power and also grid storage needs remain to grow.

Applied research at the U.S. Division of Power's (DOE) Argonne National Laboratory suggests that changing lithium-ion batteries with much better technology might be possible quicker than anticipated.

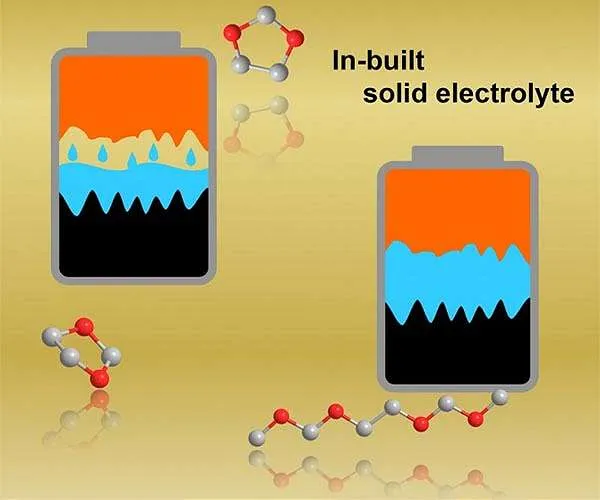

Lithium-ion batteries still require a fluid or gel to enable the battery to be charged and released; that is why older batteries occasionally leak with age. A brand-new, much safer generation of batteries does not depend on fluids or gels. Rather, these solid-state batteries use a really thin, strong movie to keep charge-generating parts (cathodes and anodes) separate and make it possible for the battery to be charged and discharged.

Chemists from across the research laboratory have actually been making discoveries in the fundamental scientific research behind solid-state batteries for years. Then scientists at Argonne's Materials Engineering Research Facility (MERF) scale up those discoveries as well as bring them closer to the market.

" Solid-state batteries can save a lot more energy, are safer, and also occupy less area," claimed Jessica Durham, of Argonne's Applied Materials department, who deals with fellow products scientist Albert Lipson to create cutting-edge solids to change liquid materials in batteries.?" The production procedures and technologies we're developing at the MERF have details benefits - faster handling, pressureless sintering, large-scale harmony and higher thickness - over those currently used."

The value of rate and also uniformity to battery manufacturing is straightforward, and also higher density enhances how long a battery can be used. Improving the sintering process is essential to unlocking every one of these benefits.

Sintering may be the bridge to far better batteries

Sintering entails heating a powder product up until it slowly develops right into a strong material with no holes or pores. This procedure is essential in solid-state batteries due to the fact that the slim material separating the cathode and also anode should be strong enough and thick enough to stand up to dealing with throughout manufacture, assembly as well as procedure. It has to likewise provide high performance; that is, the battery needs to enable fast billing, conduct electrical power well as well as last a long period of time.

By improving the sintering process, Argonne's scientists can additionally permit the replacement of the graphite material commonly used today with lithium steel. This replacement doubles the power thickness of the battery, which implies that the exact same dimension battery can save twice as much power.

Argonne puts scientific research to function

Testing and improving the processes and innovations that develop these solid battery materials at meaningful industrial scale as well as at reduced cost is the MERF's specialty. Presently, nobody generates solid-state batteries that are set you back competitive with standard lithium-ion batteries.

" In order for brand-new products to be taken on by industry, the processes to make them must be cost affordable to what is presently being done, and the materials must have considerable advantages over product in the current market," clarified Durham.?" At the MERF, we create cost-effective processes for making brand-new products by replacing expensive elements, lowering power usage, reducing waste and boosting handling conditions without sacrificing the efficiency of the product. Doing this research at the MERF enables Argonne researchers to de-risk innovations and also supply market with a ready to go, scaled-up procedure."

Argonne is one of the united state nationwide labs working to scale solid-state electrolyte materials for batteries. It does so as part of its ongoing press to scale up intricate materials and also chemical processes vital to united state competitiveness in industrial production. The 28,000-square-foot MERF has actually been crucial in assisting Argonne to progress this effort, with a tried and tested performance history of using the latest modern technologies to aid companies make new, arising materials for innovative applications

" Argonne is a crucial partner for market since we can help them de-risk new technologies or products," said Durham.?" De-risking these for industry will certainly enable them to commercialize products much faster, which will certainly save them valuable money and time. This is exactly how Argonne scientists put science to work."

Also read