Amorphous lithium exploration might cause brand-new high-performance batteries

- Researchers have actually laid out to research the kinetics of lithium deposition during biking in a battery. By changing various specifications, they've discovered that it's relatively easy to put lithium right into amorphous type, which is superior on an electromechanical degree.

The more amorphous a steel comes to be, the much better its electrochemical buildings in a battery. However, the battery sector's poster child, lithium, shows up primarily in crystalline type-- leading to a host of issues with its behavior in lithium-ion batteries.

The production of amorphous steels is especially tough. However, a team of battery material scientists just recently located a means to produce amorphous steels, including lithium, in batteries-- essentially by mishap. The group from Idaho National Laboratories as well as the University of San Diego carried out research into what occurs at the atomic degree throughout the first few moments of reenergizing a lithium-ion battery.

The researchers went over lithium's electrochemical reversibility in "Glassy Li steel anode for high-performance rechargeable Li batteries," which was recently released in Nature Materials. This reversibility determines lithium's morphology as well as its electrical residential properties. For this reason, understanding this procedure much better can bring about the advancement of higher-performance batteries.

Sluggish deposition

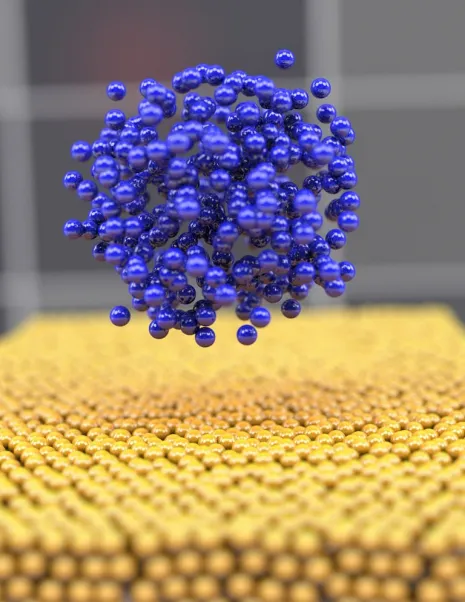

When cycling a battery, its lithium-ions down payment on the anode. The first stage of the procedure is called nucleation, where the very first tranche of metal-ions forms a base where the rest of the crystalline steel grain grows. Utilizing a cryogenic transmission electron microscopy, the group handled to picture the preliminary lithium steel deposition on the anode for the first time. As lithium deposits in crystalline form, it is the main nucleation that determines the way in which the continuing to be lithium grows around it. The scientists have actually called this procedure "lithium embryo growth".

" Depending on the atomic interaction during the initial nucleation (as an example, the atom's packing density, mass transfer and power transfer), the nanostructure of lithium cores can differ from disordered to bought, which ultimately shapes the last microstructure as well as influence the efficiency," according to the Nature Materials post.

When lithium becomes also crystalline, it charges inconsistently, after that ultimately brings about dendrite formation-- the development of irregularly designed crystals. Such dendrites significantly reduce battery life.

" The power of cryogenic imaging to find new sensations in products science is showcased in this job," stated Shirley Meng, who led UC San Diego's pioneering cryo-microscopy work. "It holds true synergy that enabled us to analyze the experimental data with confidence due to the fact that the computational modeling helped figure out the intricacy."

Much to the scientists' shock, their experiments permits them to observe pure amorphous elemental steel for the very first time. It also appeared that slow-moving billing prices supply beneficial conditions for amorphous lithium development. Formerly, the scientists had actually assumed that slower charging prices would certainly cause slower deposition rates, giving lithium-ions more time to locate a purchased structure to prepare right into, thus turning into negative crystalline lithium.

Right setting

Aside from changing the charge current to attain slower deposition rates, the researchers additionally used various electrolytes. In a "standard" electrolyte, around 48% of the lithium presumed an amorphous state. But when using what the scientists called an innovative electrolyte, 76% appeared in an amorphous kind. In both situations, the rest created crystalline structures.

According to the study, fiddling with the temporal and spatial confinements of mass and power transfer with different approaches might produce glassy steel deposits. The methods consist of methods to reduce the existing thickness, designing innovative electrolyte compositions, and also utilizing 3D present collectors.

"These approaches have the ability to alter the mass microstructure of a Li metal electrode as well as get bigger, more uniform Li deposits with enhanced biking efficiency," the scientists said.

The study group has also determined various other metals as potentially intriguing for the battery sector. They consist of sodium, potassium, manganese, as well as zinc. Amorphous metals do not create dendrites, so they can considerably boost the life process of batteries, in addition to their other boosted electrochemical properties.

"These new amorphous energetic steels will open up brand-new possibilities in different applications besides the metallic glass and energy storage fields, consisting of biomedicine, nanotechnology as well as micro- electromechanical systems," the scientists wrapped up.

Also read