A non-flammable lithium steel battery

- Scientists from Deakin University in Australia declare their battery chemistry is based upon a brand-new course of electrolyte product which brings no danger of unchecked thermal occasions and also stands for a sensible option to rechargeable lithium-ion batteries.

Scientists from Deakin University in Victoria, Australia, have actually established a lithium steel battery model which includes electrolytes created to be immune to igniting.

The development from Deakin's Institute for Frontier Materials (IFM) is stated to stand for an option to the rechargeable lithium-ion batteries utilize in mobile electronic devices, fixed power storage space as well as electrical lorries as well as is the conclusion of greater than 10 years' job by electromaterials personnel at the institute.

Patrick Howlett, supervisor of the college's Battery Technology Research as well as Innovation Hub (BatTRI-Hub) stated a 1 Ah (amp-hour)- sized lithium steel bag cell was the initial tool Deakin produced utilizing ionic fluid electrolytes which permit much better security as well as heat as well as high voltage security, to supply raised power storage space ability.

The ionic fluid is a salt which takes fluid type at space temperature level. Scientists at Deakin as well as Melbourne's Monash University have actually been benefiting 30 years on the products, which have actually started to bring in extensive passion in the battery neighborhood.

" Ionic fluids are immune as well as non-volatile to igniting, indicating that unlike the electrolytes presently utilized in lithium-ion cells-- utilized by, as an example, Samsung as well as Tesla-- they will not blow up," claimed Howlett. "Not just that, yet they really do much better when they warm up so there's no requirement for difficult as well as costly air conditioning systems to quit the batteries from overheating."

Transforming functions

Nonetheless, it is an exceptional capability to cycle energy-dense lithium steel electrodes which influenced the study initiative. IFM study other Robert Kerr, that has actually serviced converting the products right into actual tools, stated transforming battery products might transform vital attributes of the gadgets.

" For instance, if we transform the electrodes to consist of lithium steel, we can boost the storage space capability for approximately 50% longer run-times," stated Kerr. "When we alter the electrolyte, it can provide a greater discharge price or permit the battery to run at a lot greater temperature levels-- however the electrolyte has to work when touching the responsive lithium steel electrode. By selecting the right electrolyte chemistry we can entirely prevent the tragic surges triggered by ignition of the unstable electrolyte when the cell is harmed or overcharged."

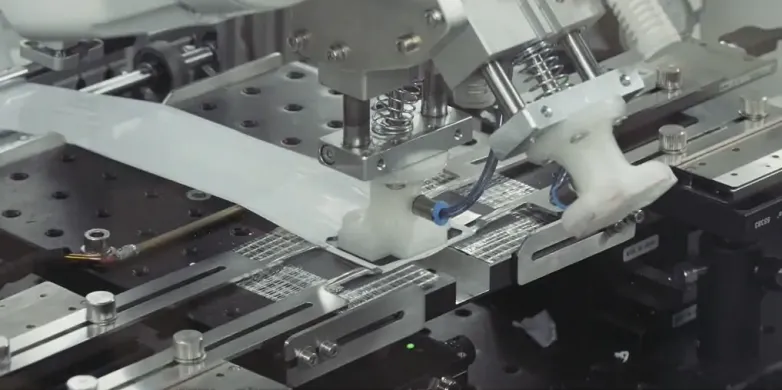

While lithium steel batteries might use much better power thickness as well as a lot reduced weight than lithium-ion innovation-- thanks to the substitute of much heavier graphite with lithium steel as anode-- lithium steels do not function well with traditional electrolytes. An additional headwind for the ingenious modern technology is the absence of expertise concerning the most effective means to manufacture cells at sensible degrees for presentation, provided making use of lithium steel electrodes in lithium steel batteries is not typical in the market. The development has actually been referred to as "simply a tipping rock heading to 1.7 Ah cells, which are quickly to be in manufacturing" however.

The project has actually been proceeding at a quick rate considering that the development of the Deakin BatTRI-Hub in 2016. The possibility of ionic fluid electrolytes is likewise being discovered under a different three-year project run by IFM as well as BatTRI-Hub with chemical maker Boron Molecular-- which was drawn out of the government Commonwealth Scientific as well as Industrial Research Organisation-- as well as modern technology firm Calix.

The project, which obtained AU$ 3 million (US$ 1.9 million) from the Australian federal government's Cooperative Research Center Projects program in 2014, intends to create high performance, affordable, quick cost as well as discharge lithium-ion crossbreed batteries based upon nano-active electrode products and also ionic fluid electrolytes. It will certainly check out using CalixFlash Calcination modern technology to create tailored micron-sized nano-electroactive products for intercalation-based anodes as well as cathodes. That would certainly be incorporated with maximized ionic electrolytes created with Boron Molecular and also Deakin, to make up to 10 kWh battery pack models at Deakin, via the Bat-TRI-Hub.

In the initial stage of the project, coin-cell manufacture, electrochemical testing and also screening of Calix's extremely permeable nano-active electrode products-- such as manganese oxide (Mn3O4) cathodes as well as titanium oxide (TiO2) anodes-- and also ionic fluid electrolytes will certainly be accomplished by IFM at Deakin. Afterwards, the BatTRI-Hub will certainly make bag cell as well as battery pack models. The project will certainly entail an area test of the battery loads, consisting of solar applications connected to tiny planetary systems as well as Deakin's wise microgrid, which includes a 7 MW solar ranch as well as a 1 MW battery. The items can after that be provided to worldwide producers as well as consumers for efficiency analysis.

Also read