A high-speed sequential deposition approach to fabricate photoactive layers for organic cells

- Organic photovoltaics, solar power devices based on organic semiconductors, have so far accomplished very promising cause experimental settings, both in regards to efficiency as well as stability. Nevertheless, engineers have not yet designed trusted approaches to fabricate these devices on a large-scale at a sensible cost.

Scientists at Wuhan University in China have lately determined a technique that can help with the rapid manufacture of photoactive layers for organic solar cells, without jeopardizing the cells' efficiency as well as stability. Their recommended technique, introduced in a paper published in Nature Energy, is based on consecutive deposition, an approach commonly utilized to deposit organic semiconductors and also perovskite movies on substrates.

" To understand the commercialization of organic photovoltaics (OPVs), the gold triangle of power conversion efficiency (PCE), security, and also expense should be thought about at the same time," Jie Min, among the researchers who performed the research study, informed TechXplore.

" Today most scientists are concentrating on these three specifications. In the power industry, nevertheless, people are paying more interest to the Levelized price of energy or power (LCOE), which is a lot more appropriate to end clients with manufacturing motivations, its computation entails many neighborhood techno-economic assumptions consisting of life cycle analysis, module operating temperature level as well as high handling throughput, etc".

To assess organic solar cells, Min and his colleagues wished to reach past the supposed "golden triangular" of efficiency, security as well as cost. Especially, they wanted to concentrate on the LCOE, which measures the typical web existing cost of electrical power generation for a particular generator or power tool throughout its life time.

The scientists feel that this measure is specifically pertinent for the present state of OPV advancement, due to the improvements they can bring in terms of efficiency as well as security. Much more particularly, the large-scale commercial growth of OPVs will just be possible when their throughput and also module return dramatically rise, which will certainly in turn reduce the total expense of solar cells.

" As an example, enhancing the throughput from 1.44 to 3.0 m2 min-1 reduces the production expense by 20%, as predicted in among our previous records," Min discussed. "This analysis supplies a prerequisite for us to discover approaches to fix the high throughput concern in the progression of module fabrication. And we think high-throughput aspect is as essential as the 3 parameters of the 'golden triangular.'".

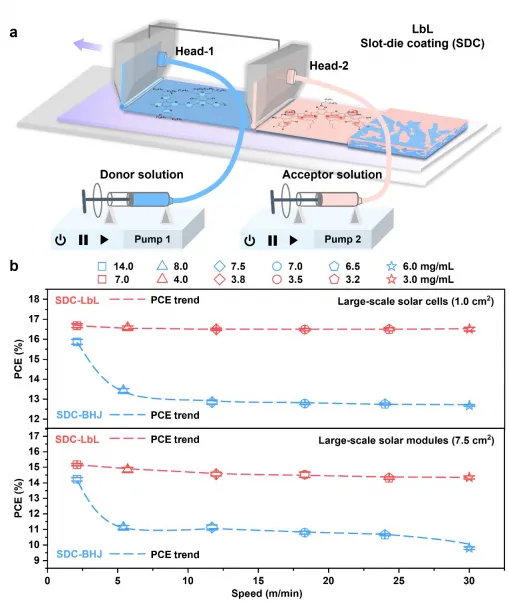

In some of their previous papers, Min and his colleagues revealed that OPV systems that exhibit high efficiencies can just be routinely blade-coated and also slot-die layered at straight speeds of 0.3-- 1.5 m min − 1. Unfortunately, these rates are still dramatically less than those acquired by silver grid electrode procedures (> 20 m min − 1) as well as interfacial layers publishing procedures (> 10 m min − 1).

" The key objective of our research study was to recognize reliable strategies to fix the high-throughput concern of photoactive layers," Min claimed. "For our joy, we were additionally able to determine a viable layer-by-layer (LbL) handling technique.".

Min and also his colleagues were able to develop a photoactive layer of OPVs with a high covering speed, utilizing an LbL processing approach. This approach involves the consecutive deposition of donor and also acceptor layers, rather than the mix of donor as well as acceptor products to develop a so-called bulk-heterojunction, which is what traditional deposition approaches are based upon.

" In our previous works, we discovered that this LbL approach can not only enhance device efficiency and stability, however additionally can get rid of the scaling lag of gadget or module efficiency," Min stated. "Other studies also showed that this LbL strategy can improve the exciton diffusion length in devices as well as overcome the molecular weight concern resulting from ideal vertical stage morphologies fabricated by LbL methods.".

The current searchings for collected by Min and his colleagues verify some of their previous searchings for, by showing that LbL processing techniques are robust and also less depending on general film-forming problems than techniques based on the donor: acceptor bulk-heterojunction. Significantly, the processing approach they recognized is additionally appropriate to non-halogenated solvents as well as operates in problems noted by high moisture.

" Our work reveals that we should not only concentrate on the golden triangle of power conversion efficiency (PCE), stability, and also expense, however additionally require to pay more interest to the vital variables (e.g. high throughput), which additionally establish the feasible applications of OPVs," Min claimed. "On top of that, I assume our work is a good beginning in moving our focus from the 'gold triangular' to the LCOE, specifically for products researchers and designers.".

As part of their recent study, the researchers made use of the LbL handling technique they recognize to create a collection of photoactive layers for OPV systems, particularly PM6: Y6, PM6: N3, PM6-Ir1: Y6, PM1: Y6 as well as PTQ10: Y6. Nonetheless, it might additionally be put on the fabrication of various other non-fullerene solar systems.

" Our work represents a step in the direction of the scalable, cost-effective production of organic photovoltaics with both high performance and high throughput," Min added. "My future research strategy will certainly concentrate on two objectives: one is to discover a suitable product system, which possesses high efficiency, excellent security, affordable of product synthesis as well as processability of high-speed covering, and also the various other is to construct a readily available gadget style.".

Also read