A graphene-based supercapacitor that’s also…. a t-shirt?

Aug 29, 2019 09:07 PM ET

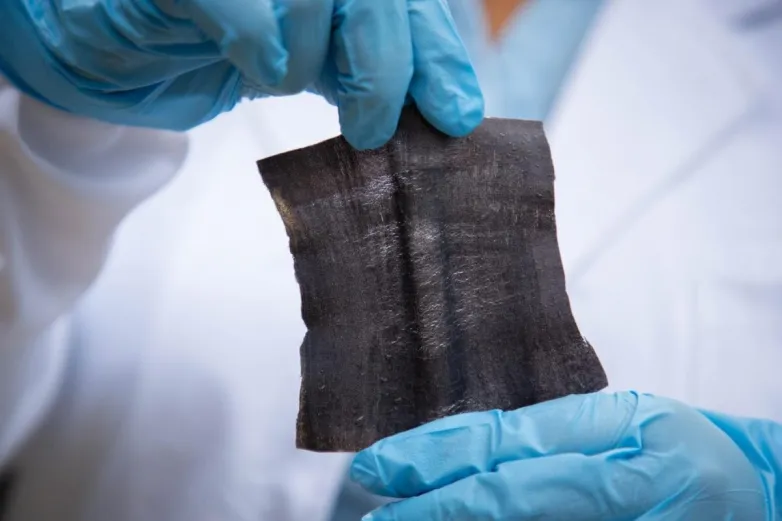

- Scientists at the Royal Melbourne Institute of Technology have developed a method for producing a ‘smart fabric’ with a supercapacitor energy storage device embedded in it. Its developers say it can be readily integrated with a solar cell or used to power wearable technology.

Scientists at the Royal Melbourne Institute of Technology (RMIT) have demonstrated a laser printing process that enables graphene supercapacitors to be embedded directly onto textiles, creating a fabric that can store energy and be integrated with a solar cell and used to power smart fabric applications.

The method is described in the paper Large-scale waterproof and stretchable textile-integrated laser-printed graphene energy storages, published in Scientific Reports, and has produced a 10x10cm patch of the fabric in just three minutes. The researchers also showed proof of concept for integrating the fabric with a solar cell and achieving stable performance for 20 days.

The fabric is waterproof and stretchable up to 200% and achieved an energy density of 6.73 milliwatt-hours per cm−2.

“Our graphene-based supercapacitor is not only fully washable it can store the energy needed to power an intelligent garment and it can be made in minutes at large scale,” said lead author of the paper Litty Thekkakara. “By solving the energy storage-related challenges of e-textiles we hope to power the next generation of wearable technology and intelligent clothing.”

Applications

Smart fabrics are an area of interest for researchers with potential applications including devices that monitor the vital signs of hospital patients or which track the status of soldiers in the field. Such garments can also power or charge a device from a bag or item of clothing.

“The realization of these self-powered technologies requires the support of energy harvesters like a solar cell,” read the paper’s introduction. “But the intermittent nature of these energy harvesters demands the association of energy storages which are cost-effective, durable, high-performance, have mechanical strength for flexibility and stretchability [and are] non-toxic and inexplosive.”

A fabric of that nature, integrated with an energy storage device, could eliminate more cumbersome solutions such as sewing battery cells into garments.

The process developed by Thekkakara and her team could also have applications in other manufacturing industries, according to Min Gu, an honorary professor at RMIT. “It also opens the possibility for faster roll-to-roll fabrication with the use of advanced laser printing based on multifocal fabrication and machine learning techniques,” he said.

Also read