A carbon scaffold to boost lithium-sulfur performance

Oct 15, 2019 10:19 PM ET

- Scientists at Singapore’s Agency for Science, Technology and Research have developed a new method to produce lithium-sulfur based cathodes which exhibit stable performance and high storage capacity over 200 cycles. According to the agency, this represents “a promising step towards the commercialization of lithium-sulfur batteries.”

Scientists in Singapore have developed a new method of producing lithium-sulfur cathodes which they said greatly improves stability during charge and discharge cycles.

Researchers at the NanoBio Lab of the Singaporean Agency for Science, Technology and Research, said lithium-sulfur batteries could theoretically have the potential to store 10 times more energy than today’s lithium-ion technology. Lithium-sulfur devices also rely on cheap, abundant sulfur. Scientists have struggled to maintain performance over repeated cycling of such batteries since the structure of the cathode tends to “collapse” during the initial cycle, greatly reducing performance.

The NanoBio Lab group used a carbon scaffold which was assembled before adding the sulfur, to create three-dimensional interconnected porous nanomaterials. The scaffold prevented cathode collapse, according to the researchers.

Results published in Nano Energy indicated batteries incorporating NanoBio Lab’s new electrode achieved specific capacities as high as 1220 milliamp-hours per gram and a capacity fade rate lower than 0.14% over 200 cycles. According to the lab, that represents a 48% improvement in specific capacity and 26% lower capacity fade than previous efforts with lithium sulfur batteries, thanks to “differences in morphology, surface area and ohmic resistance of the cathodes”.

Nanomaterial engineering

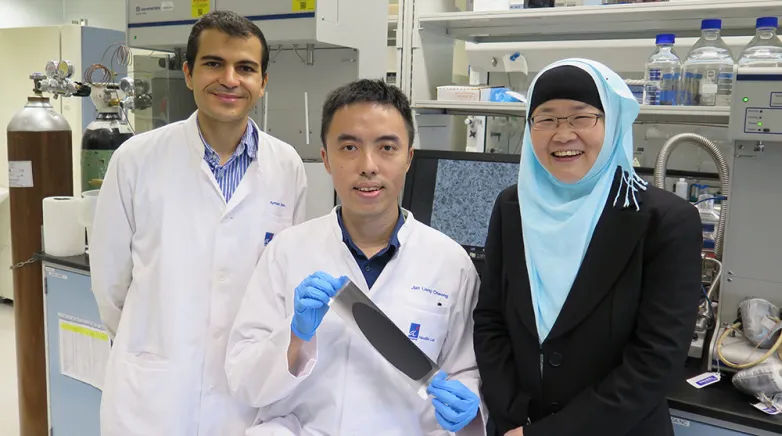

“We have shown that the preparation technique of sulfur cathodes has a strong influence on the electrochemical performance in lithium-sulfur batteries,” said Professor Jackie Y. Ying, who led the NanoBio Lab research team. “Our method is industrially scalable and we anticipate that it would have a significant impact on the future design of practical lithium-sulfur batteries.”

While lithium-ion batteries have taken the energy storage market by storm – and the technology’s pioneers were last week awarded the Nobel Prize for Chemistry – there are several drawbacks inherent in the technology, particularly in terms of long-term performance, safety and a reliance on rare materials.

Lithium sulfur batteries are among several contenders to be optimum solutions to large scale storage technology. Other options include lithium metal devices, solid state and calcium batteries.

The NanoBio Lab researchers said they will focus on improving their cathode design as well as using nanomaterial engineering to optimize the anode, separator and electrolyte. The ultimate goal, according to the laboratory, is to “develop a full cell system for [a] lithium-sulfur battery that has superior energy storage capacity, as compared to conventional lithium-ion batteries”.

Also read